If you use CNC milling or CNC router machine in workshop, here is complete explanation how does cyclone dust collector work on the cnc router machine.

Table of Contents

Cyclone dust collector for CNC router

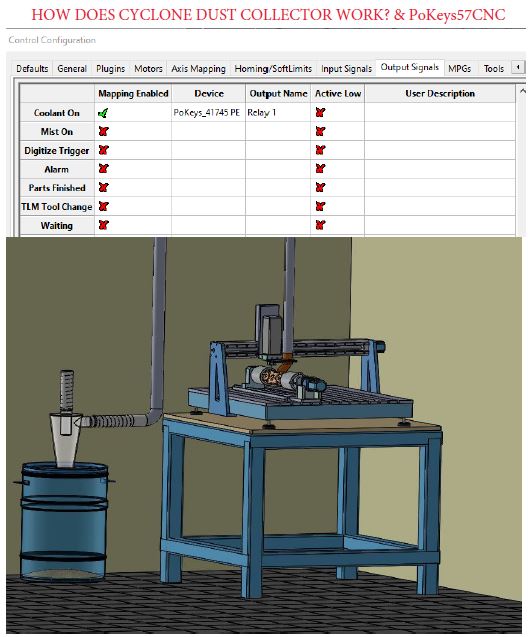

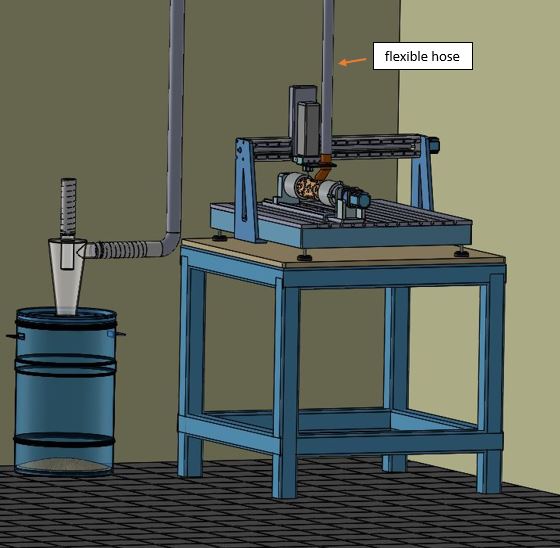

In our workshop, we develop and manufacture different types of products and materials for our needs or customers. Many times we have had problems with dust, debris. So we decide to upgrade- add it on the CNC machine and have perfect extraction for our work. Cyclone separator dust collector we control with CNC controller. Cyclone dust collector is connected on CNC controller and we turn ON/OFF it with G code. Turn ON/OFF we config on G code M08 (ON) and M09 (OFF). PoKeys57CNC have Relay output and we turn on/off dust collector and also spindel motor.

What is a cyclone dust collector?

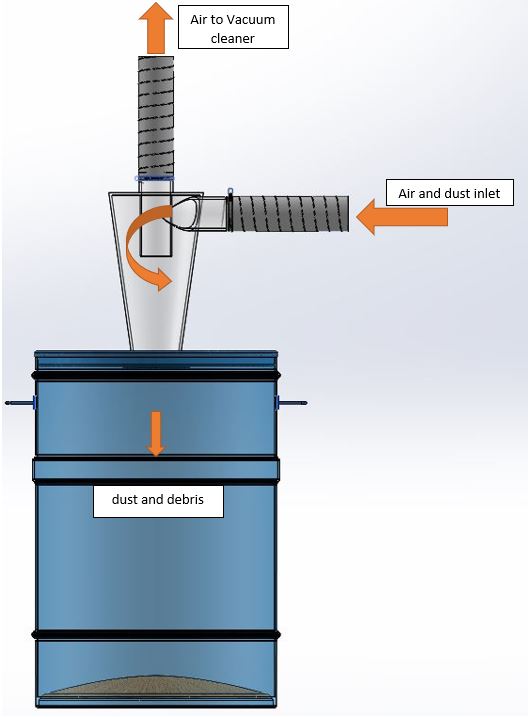

A cyclone dust collector is a useful device, which is connected with dust collection hose to the device (machine, CNC…) which produce dust and with shop vacuum cleaner or other device which generate vacuum. The working principle of device is described and presented in chapter below.

How does cyclone dust collector work?

Cyclone dust collector operating/working principle is simple. Dust entering through hose from machine( cnc..) or other device to the cyclone, there dust start circulating. Material/dust which came into cyclone collector spins on wall in an cyclonic motion. The centrifugal force pushed down the dust because the shape-form of the dust collector and material spins it faster and fall into cask. The mechanically separations is very efficient, in data efficiency is near 99% and after the test with a different type of materials and different thicknesses the system works properly and efficient is really high.

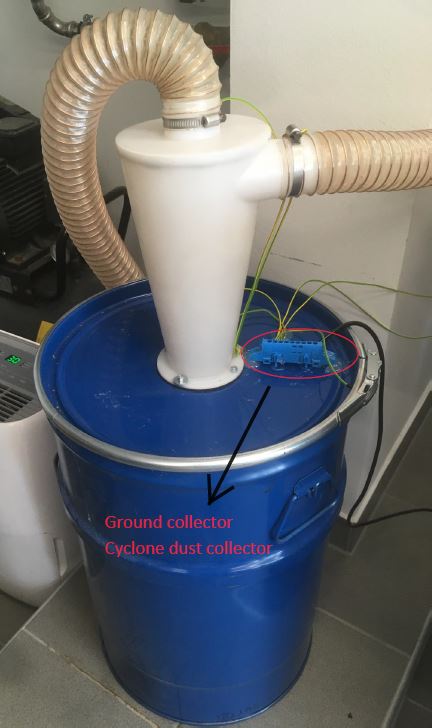

When the system works and material-dust through hose came into dust collector, we producing static electricity depending on type of material. When we works with plastics material or wood is because of motion through hose generating static electricity. It is important we use quality parts ( antistatic hose) and system must be grounded. Pay attention on grounding, positions where we put together hoses, hose clamps, cask must be properly grounded ( in photo below) and connected to the socket(ground) or independant. It is important to ground well otherwise you can have problems with electronics.

Cyclone dust collector working principle

advantages:

- easy to clean,

- all dust stay in the dust collector,

- better cleaning,

- easy to operate and cleaning the barell,

- adapt your system to your needs,

- simply for use,

- use for many materials: wood, metal, plastics, mining…

Before we start the project, we saw a lot of versions/implementations of cyclone dust system. So we decide to use/made most parts for our system. For system we 3d print a lot of usefull parts which we use in implementation for our project. Working principle of system is easy and system works properly and fine.

How do you make-assemble cyclone collector?

We decide to make it ourselves. We have had a vacuum cleaner before, so we need to figure out best way how to install suction pipes and which type of dust collector we will use. Main parts: vacuum cleaner and dust collector we have in the workshop, so we need to check which other parts we need to buy or make.

For assembly is very important to have quality parts, because it is easier to make good product or solution and a quality solution in our case upgrade machine with an automatic suction system.

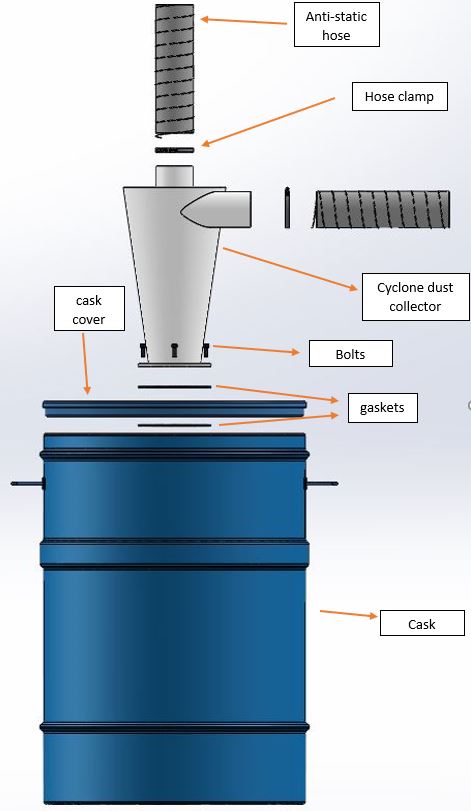

- Anti-static hose ( important),

- hose clamps,

- gaskets (betwen cask cover and cyclone collector),

- cask ( we use metal cask- 60l volume),

- bolts,

- cask cover ( with gasket).

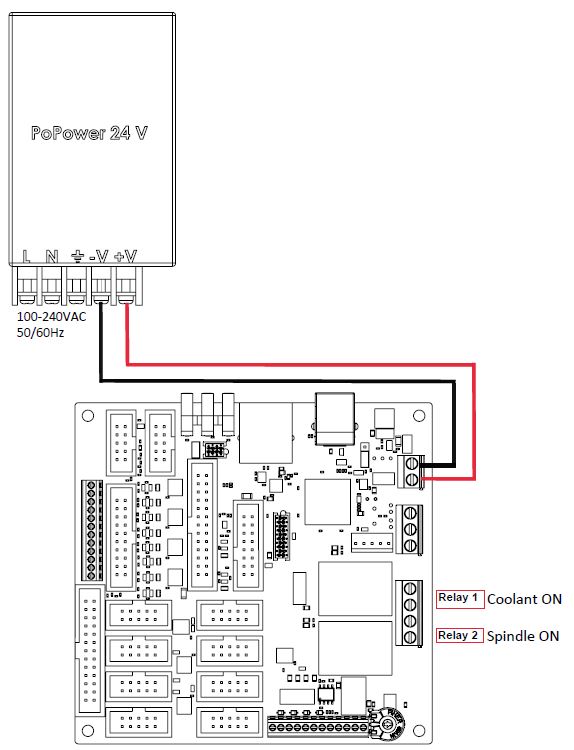

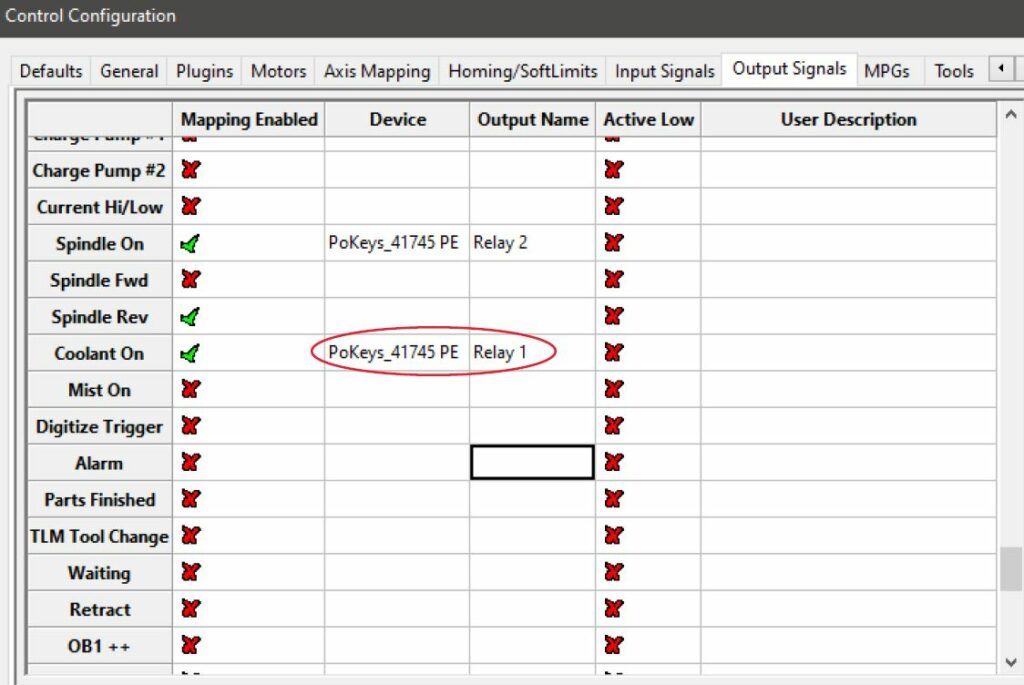

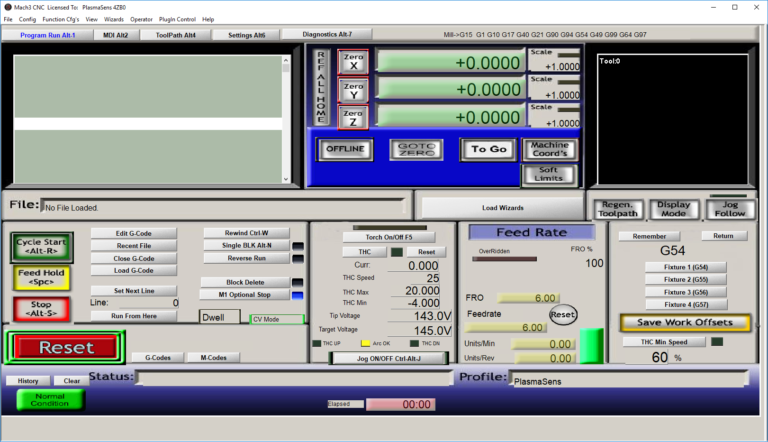

How to setup and wire & Configuration in MACH4

Finally we arrived to wire, setup and configuration vacuum cleaner( dust collector) in Mach4. After mounting elements/parts mechanically in workshop and modify a system to our needs, we must decide how to tun ON/OFF vacuum cleaner. We decide, for turn ON/OFF we use our CNC Controller, because we have 2 power socket in control box in which we attach cyclone collector (vacuum cleaner) and spindle motor. If you dont have power socket on your controller box, it is few steps to install, configuration it on Pokeys57CNC and use device features.

- Firstly: wired the relay module with peripheral device ( vacuum cleaner, spindle motor, VFD…),

- Secondly: Configurate Output signals in Mach4 program, and you can turn ON/OFF it with M code.

In our case we use output signal for Coolant ON (photo below), because we dont have coolant system on our machines and it is easy to keep in mind which M code use for turn On/Off(M8/M9) the system.

Cyclone dust collector and system works properly and fine, we recommend the cyclone dust collector.

More about

PoLabs web page,

More information about Pokeys I/O devices.

If you need information about Polabs – PoKeys products, here are some links:

Please check also our latest blog posts. It can help you to improve your machines or get some ideas on how to even make them better

- Stepper motor driver-complete explanation

- USB CNC Controller-PoKeys57CNC

- Homing sensor

- Bipolar stepper motor driver – PoStep25-256 – product

- PCB tester – for PoStep25-256 – blog

- 4th axis for CNC -blog

- Introduction to CNC hardware – electronics – blog

- plasma cutting equipment – blog

- what is CNC plasma cutting – blog

- what is a CNC plasma floating head – blog

- Plasma cutter troubleshooting guide – blog