Table of Contents

What are CNC plasma cutters used for?

CNC plasma cutting is the manufacturing process of cutting the material with plasma. The CNC plasma cutting process is a very well-known manufacturing process, which was used during 1980. Plasma cutting grew out of plasma welding in the 1960s and emerged as a very productive way to cut sheet metal and plate. It had advantages over traditional cutting with producing no metal chips, giving accurate cuts, and producing a cleaner edge.

CNC plasma cutters are used for cutting sheet metals, metal signs, metal arts, metal tubes and pipes, and other metal fabrication projects. CNC plasma cutters are also used in many workshops to create decorative metalwork. For instance, commercial and residential signage, wall arts, outdoor garden art. Plasma cutters are not only professional CNC machines since there is a lot of DIY CNC plasma cutters project, which depends on needs, workshop space, finance…

How does CNC plasma cutter work?

CNC plasma cutter machine is specifically designed to cut through electrically conductive material by using a computer to control and direct an accelerated jet of hot plasma at the material being cut.

CNC plasma cutting machines are computer-run systems that have the ability to move a high-definition plasma torch in various directions by using numerical coding(G-code) that has been programmed into the computer. The plasma cutter itself operates by forcing a gas or compressed air through a nozzle at high speeds. An electric arc is then introduced to the gas creating a plasma that is able to cut through metal.

CNC plasma cutters are available in different sizes, prices, and functionalities. These machines are highly accurate and can cut through material up to 40mm with speeds up to 700mm/min. While high-definition cutters require gas and assist gas to function, the type of gas will vary depending on the material being cut. More about gases is described in one of the chapters below.

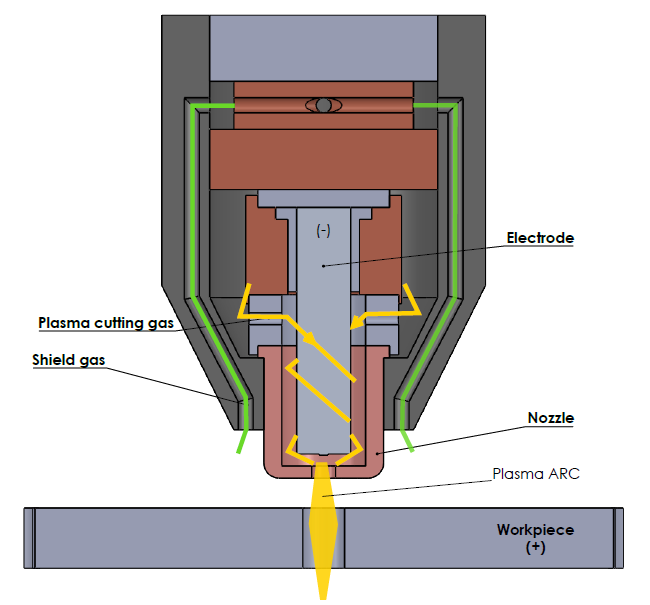

Plasma cutting torch

The plasma torch is one of the most important parts of a CNC plasma machine. Why? Quality of product (electrode, air diffusor, nozzle, external nozzle…), the start of cutting, cooling of the torch, everything makes for more reliable setup and better cut quality.

Torch options: Short, long, angled, straight. Torches are made for both hand-held and mechanized cutting and gauging, as well as CNC or robotics cutting. The torch usually comes with the plasma cutter and although budget is often biggest concern, on the long run, it is always beneficial to invest a little more in high quality equipment.

Gas types

The best gas to use depends on three primary considerations: cut quality, productivity, and economy.

- AIR: Air is the most versatile plasma gas, it produces good cut quality and speed on stainless steel, steel and aluminium. Air also lowers costs because it is not necessary to purchase gases. However, air is not free. Shop air must be cleaned to remove contamination such as oil mist, moisture. Air is a good option for many shops for its versatility, good speed, low dross levels, and parts life up to 600 starts.

- OXYGEN: Oxygen has become the standard in the industry at cutting mild steel, because it provides the best, clean-cut quality and the fastest cutting speed of any plasma gas. However, a plasma cutting aluminium or stainless steel plate with oxygen plasma gas is not recommended. The disadvantages of oxygen are the cost of the gas and the life of consumable parts. State of the art plasma oxygen systems use inert starting gases, such as nitrogen, to archive similar parts life to nitrogen or air systems. These systems have parts life in the 800-1500 start range.

- NITROGEN: Nitrogen was used in most early plasma cutting processes. It is still the best choice if you cut a lot of stainless steel or aluminium. In general, air is the best secondary gas, when using nitrogen plasma. CO2 also works well, slightly improving the finish, cutting speed and parts life over the use of air.

- ARGON-HYDROGEN: Argon hydrogen is the plasma of choice for thick stainless steel and aluminium cutting. The mixture typically uses 35% hydrogen and 65% argon. Argon hydrogen is the hottest burning plasma gas and provides the most cutting power. Argon hydrogen is used in water injection torches to up to 1000 amps to cut up to 6″ stainless steel. Its provides a straight cut and a smooth, almost polished surface on stainless steel. Nitrogen in usually used as a shield gas with argon hydrogen. The disadvantage of this set up is the expense.

- Other gasses used in CNC plasma cutting are nitrogen and methane, which are most often utilized when cutting thin stainless steel.

CNC plasma table frame and slats

The CNC plasma table is the skeleton of the CNC plasma machine. The motion for the X and Y axis is utilized as well as Z axis for mounting the plasma torch. There are many options for plasma table. It is important to use components and equipment that are resistant to heat and dirt.

Slats are the webbing that is done on the machine table that supports the parts that you are cutting. The parts of the slats are disposable, since after a lot of cutting they become worn out and cut all over the place and do not support material properly anymore.

Fume control system

Whether using water or down-draft, the fume control systems act as your system’s filter, working to dispose of the waste air produced during the cutting process. It is important to use a filtering system and protect equipment because othervise it is a health concern.

Z axis and floating head with THC torch height contol

The simplest plasma cutters have only X and Y axis and torch is stationary with regard to height. That is ok for lower quality cuts, but for high quality cutting, THC – torch height control is recommended. It solves the problem of warped metal sheets that cause the distance, between the part and the torch to vary. THC with CNC Plasma floating head enables to adjust and maintain the distance between the workpiece and the torch so the cuts are precise and crisp.

The THC works with first probing the torch to the surface of the workpiece with torch disabled. Then the torch is raised to the working distance and fired. With plasma cutting, plasma voltage is determined with the distance to the workpiece and there is a value of voltage (distance) where plasma performs the best and cut is as good as it gets. That can be done with our PlasmaSensOut unit.

After the plasma is fired, the CNC controller with THC option monitors the voltage and with varying the Z axis maintains the optimal voltage and distance to the workpiece.

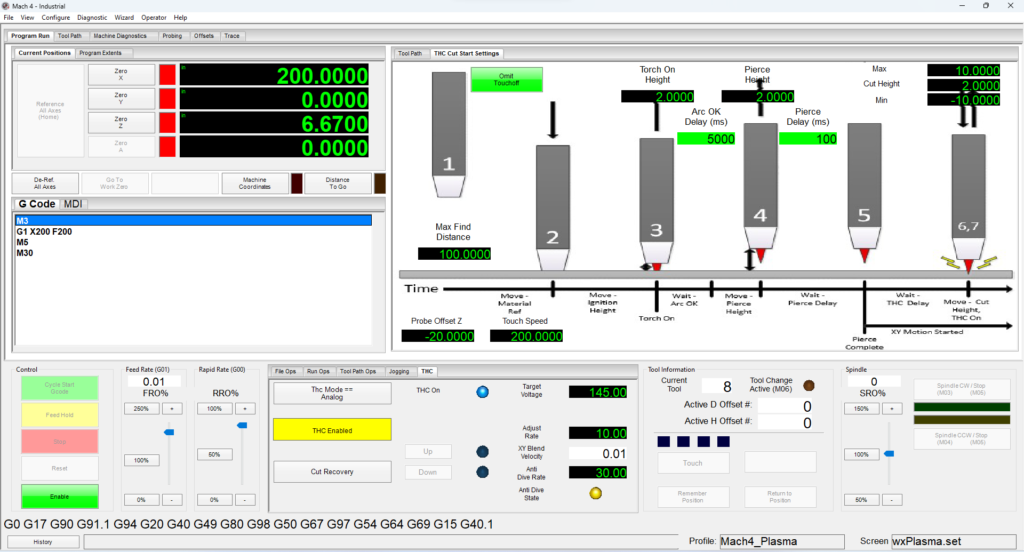

Plasma cutting software

Although most CNC plasma cutters will come with their own software packages, including some form of CAD platform, others may not. On market, we have many different CAD/CAM programs. Some programs are also free.

Many machines on the market and a major part of home build machines use MACH3 and MACH4 plasma software. We would strongly recommend it because it is very versatile software and you can configure the machine to your needs and can add a lot of devices and sensors with multiple options for configuration. It also supports THC option with our controllers.

Why should you build a CNC plasma cutting machine?

CNC plasma cutting machine is a very productive and cost-efficiency machine.

This ensures happy customers on your end, which often turn into repeat customers. Because you will be producing more cuts that are high quality and retain happy repeat customers, investing in a CNC plasma cutting system is a smart choice that will more than pay for itself in a short matter of time.

A CNC plasma machine is easy to use and requires minimal training to learn how to operate effectively. This drastically reduces onboarding costs for shops looking to hire machine operators and also provides increased accessibility for one-man shops looking to add a CNC plasma tool to their arsenal.

About

Polabs, develop and manufacture electronic products for many different areas and needs and also make some machines to make work easier, more productive and high quality. Here are some interesting projects- blog posts, please check.

- PCB testing equipment

- How does a cyclone dust collector work

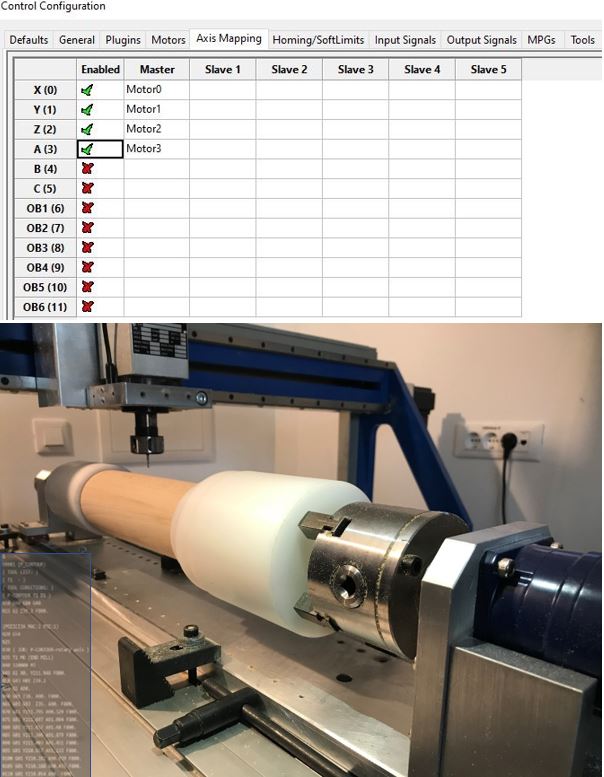

- 4th axis for CNC

- Homing sensor

- Plasma voltage divider (NEW product)

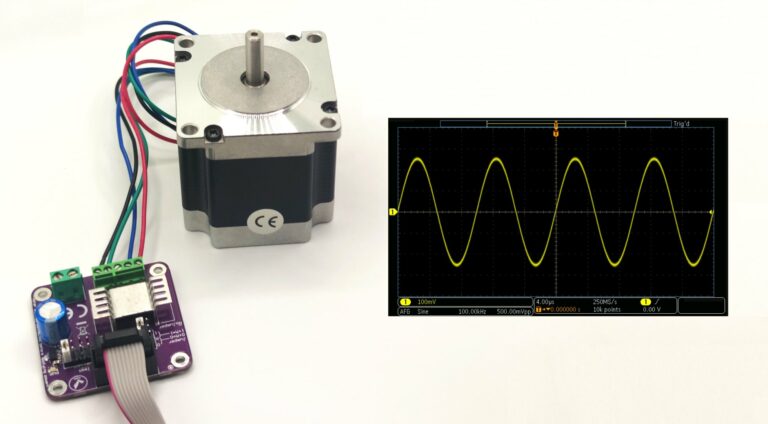

- Introduction to CNC hardware – electronics

- Plasma cutting equipment

- CNC plasma floating head – Z-axis

- PCB tester – PoStep25-256

- Bipolar stepper motor driver – PoStep25-256