In this blog we tried to list the most common plasma troubleshooting issues and help you to get on your way. Our goal is to help our customers as fast as possible in simple and exactly. This is reason for creating new blogs, for introduce products, solutions and try to solve some open questions. Described plasma cutter troubleshooting guide based on user experiences with PoKeys products.

In blog (What is CNC plasma cutting), we described bases of CNC plasma cutting, how does it work, how CNC plasma table is build, how to setup the machine.

Table of Contents

Plasma cutter software troubleshooting guide – Mach3&Mach4

PoLabs team always listens to your feedback, considering ideas, and uses them for improvements. Support response times are short and always looking forward to solving your problems.

The plasma cutter software troubleshooting is depend most on Mach3 and Mach4. We recommend the latest version of the software: Mach3 software and Mach4 software.

PlugIn

For easier solving problems in the system, we recommend the latest PlugIn version. The latest version you can find in downloads.

Plasma cutter wiring troubleshooting guide

Wiring troubleshooting, most open questions, and problems when building CNC plasma cutter and wiring the CNC electronics components with plasma, torch, switches, drivers are:

- Problems with wiring:

Make sure the optical cable is connected properly. Remove the protective caps from the optical cable before inserting them into the plug. You should feel a click when inserting.

We would advise a separate main power outlet for the cutter and electronics. Put some ferrite chokes on the cutter’s supply cable. Make sure your grounding is OK and use shielded cables for stepper/servo motors.

It is always a good idea to put electronics in the grounded cabinet since plasma is a huge EM interference generator.

There are some suggestions:

- Firstly use a separate main power outlet for the cutter and other electronics,

- Then use short power supply cable for the cutter,

- Use short wires for connections,

- Use shielded cables for servo/stepper motors,

- Install electronics in a metal cabinet and make a good grounding of it.

Why does my plasma cutter keep stoping-troubleshooting guide

A plasma cutter is a great source of electromagnetic interference. So special care should be taken into account when designing and wiring machine electronics.

Be sure to use shielded cables for motors, limit switches. External power supply for motion controller is very recommended. Plasma cutters themselves sometimes do not satisfy standards of electromagnetic compatibility (EMC), so make sure that your plasma cutter is within EMC regulations

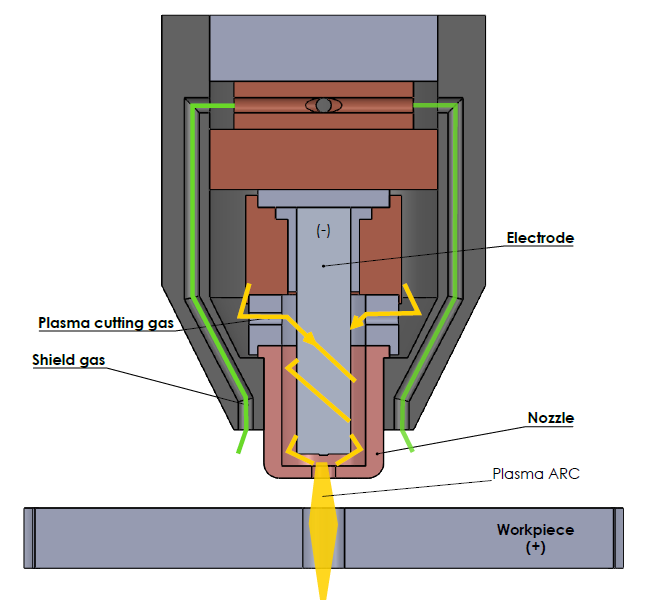

Plasma cutter not arcing

Poor contact between ground wire and workpiece.

Grounding is an essential preparation before cutting. Reasons for poor contact can be in-ground wire, in the workpiece surface (oil moisture, oxidized surface).

Torch nozzles and electrodes burn out.

Burn out or damage of the Torch assembly parts is a consequence of:

- Impropper installation of the nozzle, such as untightened thread fastening, incorect assemblying the torch.

- The cooling medium doesnt flow as required when the cuting torch which needs to be cooled with cooling medium is working.

Insufficient Or Excessive Air Pressure

Air pressure is a very important setting in the plasma cutting process. It is important, each manufacturer of torches has its own pressure requirements. Make sure to have an air regulator implemented in a compressed air system. We all know we need dry and clean air.

For the best performance, it is important to filter the air yet again. We recommend adding an air filter again at the gas inlet. It prevents water and particles from reaching the plasma cutter.

Too high air pressure

If the air pressure is too high, after the plasma arc formation, the excessive airflow will blow away the concentrated arc column and weaken the cutting intensity of the plasma arc.

Causes of high air pressure include:

- Air filter pressure valve-regulated too high,

- Air filter valve failed,

- Improper input air conditioning.

Too low air pressure

If the working pressure is far lower than the pressure required by the cutting equipment specification, it means that the plasma arc ejection speed is weakened, and the input airflow is less than the specified value.

Causes of high air pressure include:

- Air channel is obstructed,

- The compressor is short of air,

- Air filter pressure valve-regulated too low,

- Check air tube.

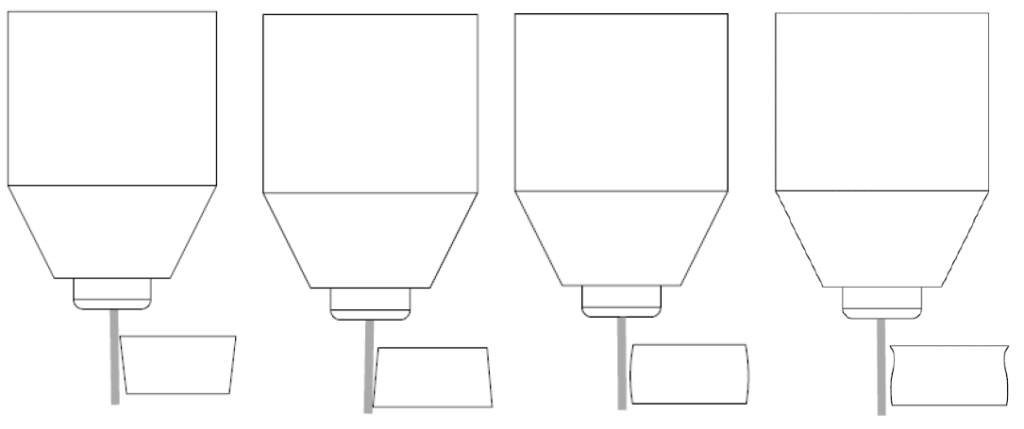

Plasma cutting quality

A combination of correct-fast cut speeds and low operating costs, makes plasma cutting the most productive metal cutting process. You need to keep your plasma system and table in good shape. Correct and preventive maintenance is key for better system performance and consumable life.

In the cutting process, there are a lot of variables that can affect plasma cut quality. Some of the variables include:

- Torch type

- Torch alligment

- cutting height – Arc voltage (THC)

- Gas type

- Gas pressure and flow

- material thickness

- cutting speed

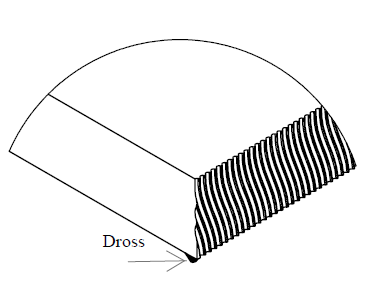

Most of these variables are interdependent (if you change one variable, it will affect the others). There is the reason, why figuring out how to fix-improve cut quality is difficult. Most prominent conditions in CNC plasma cutting – quality:

- Cut angle,

- Surface roughness,

- Dross.

Cut Angle

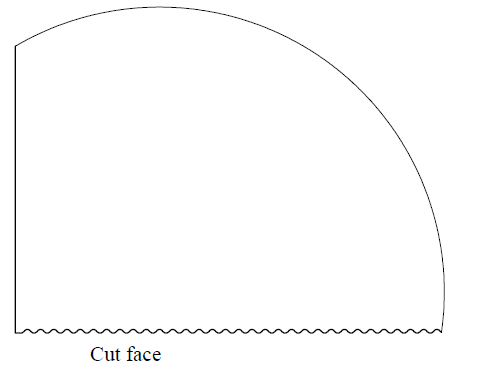

Negative Cut Angle

If the top dimension of a part is larger than the bottom dimension. This can be caused by:

- warped material,

- low arc voltage,

- cutting speed to low,

- cutting torch is not parpendicullary to surface.

Positive Cut Angle

When the top dimension is smaller than the bottom dimension. This can be caused by:

- cutting torch is not parpendicullary to surface,

- cutting speed to high,

- high arc voltage,

- warped material.

Top and Bottom Rounded

This usually happens when cutting thinner materials (less than 6mm) thick. It is most often caused by overpowering the material, too much amperage.

Top Adge Undercut

It is most likely caused by cutting with the torch too close to the material. When the ARC voltage is set to low for a given material thickness.

Surface Finish and Dross

Surface finish and dross it is dependent by:

- Process induced: gas flow, cutting speed, torch height.

- Machine induced: dirty machine rails, rack/pinion, rails out of alignment, bearings damaged/loose.

Recommendation for torch height control

If your CNC plasma doesn’t have a THC, a profiling machine to get one. If you are buying a new CNC plasma machine, get the best THC.

A good THC (Torch heigh control) with all controls will pay for itself in improved parts life, enhanced cut quality, and better cutting time.

About

Polabs, develop and manufacture electronic products for many different areas and needs and also make some machines to make work easier, more productive and high quality. Here are some interesting projects- blog posts, please check.

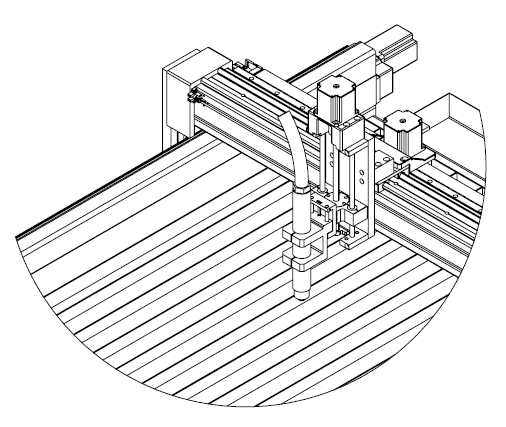

- USB CNC CONTROLLER – PoKeys57CNC,

- Plasma voltage divider,

- Adapter board 10V-3.3V plasma,

- Torch height control,

- What is CNC plasma cutting?

- Mach3 plasma setup,

- THC plasma cutter

- Plasma cutting equipment.

- Introduction to CNC Hardware – electronics

- CNC plasma floating head – Z-axis

- PCB tester – PoStep25-256

- Bipolar Stepper motor driver – PoStep25-256