Here is a quick guide how to easy perform Mach3 plasma setup. This article will guide you through the process of setting THC with your CNC controller board and Mach3.

Let’s get to the point! How to use plasma with Mach3?

Table of Contents

Mach3 plasma setup quick guide

First let me briefly introduce our two product from torch height control and the difference between them. PlasmaSens and PlasmaSensOut are design on modern 32 bit microprocessor’s voltage measurement technology. Moreover device offers two arc voltage level inputs. High voltage input up to 350 VDC or low voltage input up to 10 VDC. The last one is suitable for cutters with internal voltage divider output. However, PlasmaSens comes with optical interface and is meant to be used with CNC controller board PK57CNC. While on the other hand PlasmaSensOut comes with the user friendly HMI device and can be connected with any other CNC controller board. PlasmaSensOut namely generates universal THC control signals Arc_OK, Torch_Up and Torch_Down.

First we will describe the case with PlasmaSens and PK57CNC. Description for PlasmaSensOut can be used to setup any other generic CNC controller board.

Table of Contents

Mach3 setup

If you will working with Mach3 for the first time here is a link where to download it: Mach3 download page. I also advise you to browse on a YouTube how to start with Mach3. We will run Mach3 Plasma profile.

The next thing if you are going to use PlasmaSens with a PK57CNC controller is to download the PoKeys configuration package and run the installation. The PoKeys Mach3 plugin will be automatically installed along with the app. To be sure, you can check if PoKeys.dll exists in C:\Mach3\PlugIns folder. It is always a good idea to install the latest application and plugin version!

In this article we will focus on a THC setup options and we will assume that we already set the axis, motor parameters and limit switches.

PlasmaSens

First we have to power up PlasmaSens and establish communication with PoKeys57CNC. Connect AC power supply (110 VAC-230 VAC/50-60 Hz) and apply optical cable to PlasmaSens and optical interface. Make sure you remove plastic caps at optical transmitter/receiver and protection caps on the optical cable. When you insert the cable, you will feel a click.

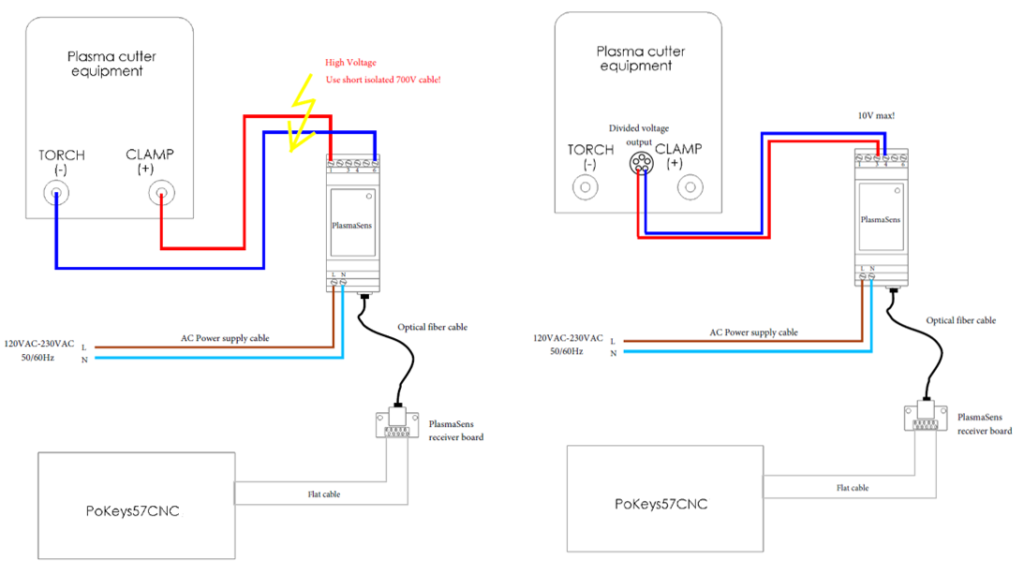

How to connect to cutter’s voltage?

There are two ways. The first is connecting directly to cutters output. In that case you will probably need to do some adaptation on the cutter itself as usually doesn’t have such an output. Make sure you use a double isolated short wire for voltage detection. You should use a HV input terminal pin1 and pin6. Watch for polarity! A cutter’s clamp is positive voltage potential and it goes to pin1.

The second way is using an divided voltage that some plasmas manufacturer have factory installed. 50:1 ratio will be perfect for PlasmaSens 10V input (pin-3 and pin-4).

Click to enlarge: connection to HV or divided output

Click to enlarge: connection to HV or divided output

Connect optical interface flat cable with red micro-match connector to PoKeys57CNC (PoExtension2). All setting regarding THC we can do it in PlugIn control -> Configure PoKeys57CNC -> Pulse engine settings tab.

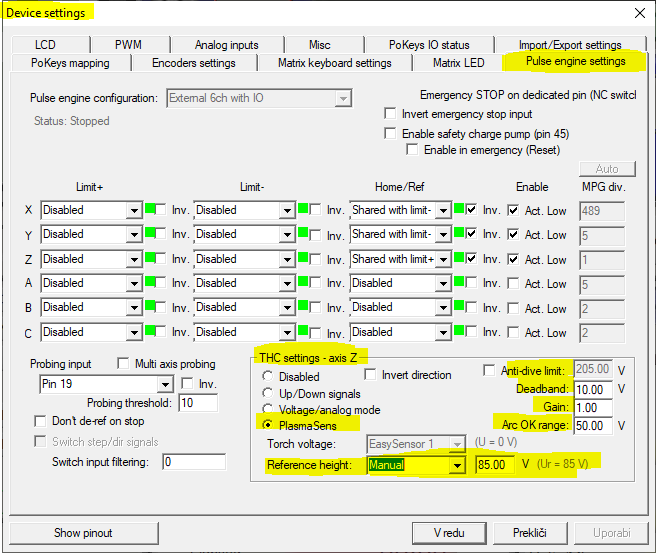

Choose PlasmaSens in THC setting -axis Z section group.To use a split 10V input, you must select the Easy Sensor (ID) number that corresponds to the PlasmaSens 10 V input. However you must first select Voltage/analog mode to be able change Torch voltage input and then switch back to PlasmaSens.

Parameters

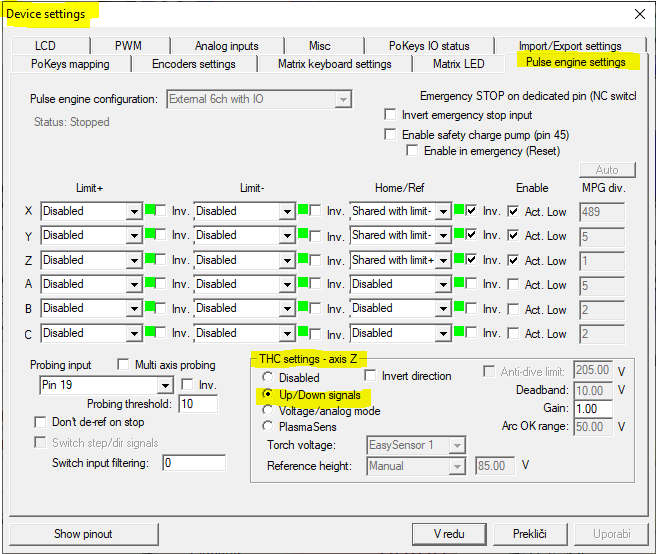

Reference height-> Manual and write the rated operating voltage value of your cutting machine.

Deadband – voltage hysteresis (voltage frame around reference height, a range where the position of the Z-axis is not changing).

Gain – correcting motion gain (reduce the gain if the torch height is oscillating).

Arc OK range – voltage range where THC will be active (reference height ± arc OK range).

The plasma cutting is pretty delicate thing so you should do some experimental cuts to achieve best settings for your cutter’s equipment.

PlasmaSensOut

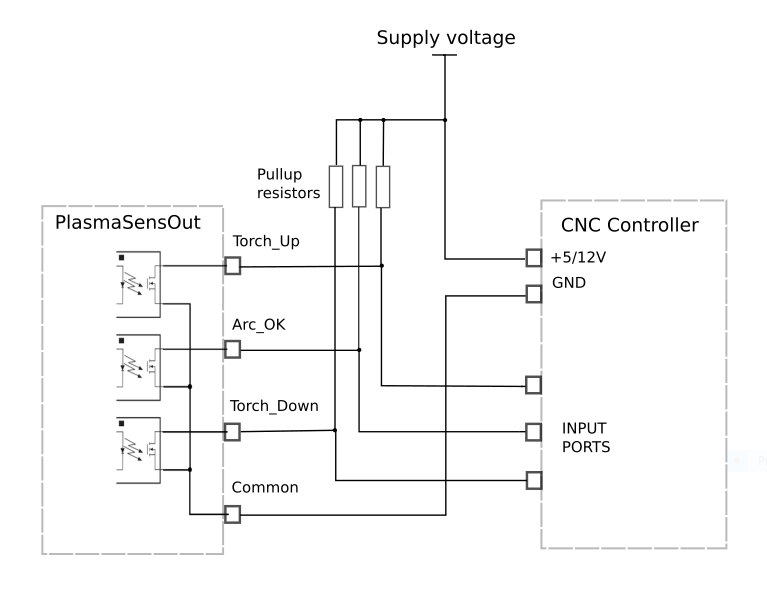

Installation of PlasmaSensOut system is to a good extent the same as installation PlasmaSens. But in this case we connect the optical cable to the HMI device. The device also need external DC power supply voltage (6V-36V). PlasmaSensOut has three standard THC output signals (Arc_OK, Up and Down).

The outputs are of the solid state relay type. That means low resistance (Ron< 0.6 Ohms) between output and common terminal when active. If I generalize we use them as normally open switches. That’s why, at controller board side, inputs should be pulled up as it is already done on PoKeys57CNC. In case your controller board hasn’t got pull up resistor on input ports, you must apply external pull up resistor. Normally the resistor 1kOhm, between each input and power supply line, should be appropriate. We must connect the common terminal to GND at CNC controller board! Mach3 plasma setup using THC up, down and OK signals we described in the next section.

Click to enlarge: connection when no pullup on controller side

Click to enlarge: connection when no pullup on controller side

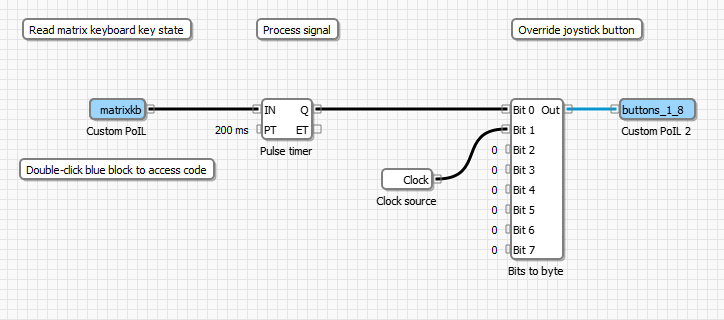

Mapping PlasmaSensOut signals in Mach3 PoKeys plugin

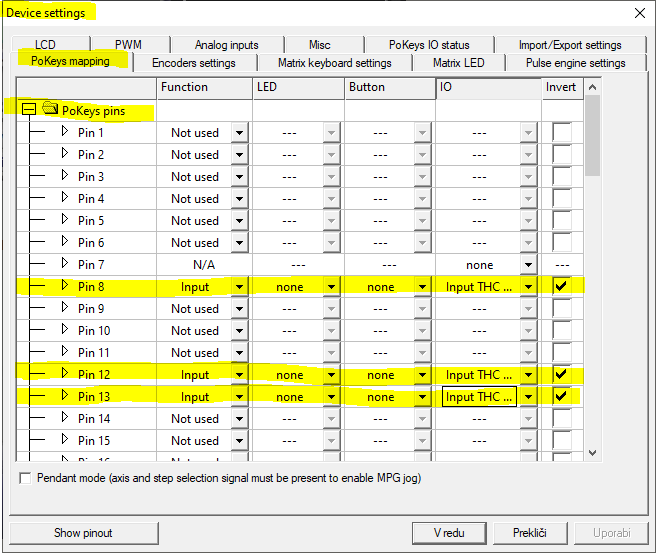

In Mach3 software under Plugin Control-> Configure PoKeys57CNC->Device settings you will find PoKeys mapping tab. Map connected pins as shown below. In our example we select PoKeys pin 8, 12 and 13 as input.

Signals mapping in PoKeys plugin

Signals mapping in PoKeys plugin

In Pulse engine settings tab in group THC settings-axis Z select Up/Down signals.

HMI menu option

Press V / ꓥ button to set Reference Voltage value.

To enter a setup menu press and hold • button for one sec. The LED display will start flashing then the setup menu will appear. Select the parameter you would like to change by pressing V / ꓥ button and confirm with • button. Press V / ꓥ button to modify parameter’s value.

Sdt – Set delay time from 0.1 to 9.9 sec. Time between Arc OK signal appears and generation of signals up and down is enabled.

HYS – Hysteresis from 2V to 32 V (2 V step). Voltage frame around reference. If arc voltage is higher than Ref + HYS/2 then down signal is generated. If voltage is lower than Ref – HYS/2, up signal is generated (see the output signal example below).

AdL – Ant-dive limit from 50 V to 300 V. Arc voltage that disables THC. If voltage goes higher than Anti-dive limit all output signals go low. The parameter’s value must be set higher than reference voltage.

tSt – Test mode. Only available when no arc voltage present! Pressing V or ꓥ button generate output signals. The display indicates a simulated direction.

HMI – LED display and navigation buttons

HMI – LED display and navigation buttons

Plugin options- extra

Inside Plugin Control-> Configure PoKeys57CNC->Device settings there are some additional options at Pulse engine settings tab .

As we already described, we can select up/Down signals, PlasmaSens or not mentioned yet Voltage/analog mode option. If we selected the last option, we can select Torch voltage input to be one of the EasySensors or one of PoKeys analog inputs. Be aware max 3.3V can be apply to the PoKeys analog input pin!

There are few options for a Reference height. We can choose between manual, one of the analog inputs or OEM DRO1601.

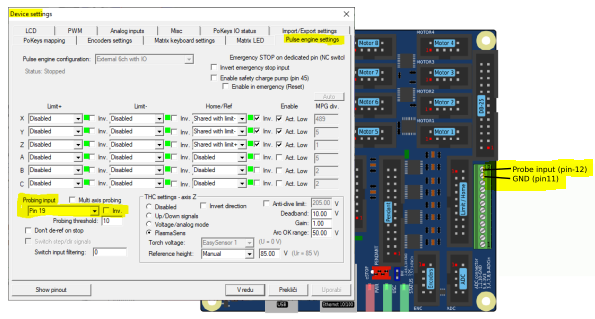

Probing input: select the probe’s input invert it if necessary and set the threshold!

Probe setup (floating head)

The floating head switch (Z- axis probe) is also an important Mach3 plasma setup. In our case we select Probing input: Pin 19 and connect the switch to PoKeys57CNC between pin-11 and pin-12 as marked on picture below. NO or NC switch can be used thanks to “inv” option in the plugin setup.

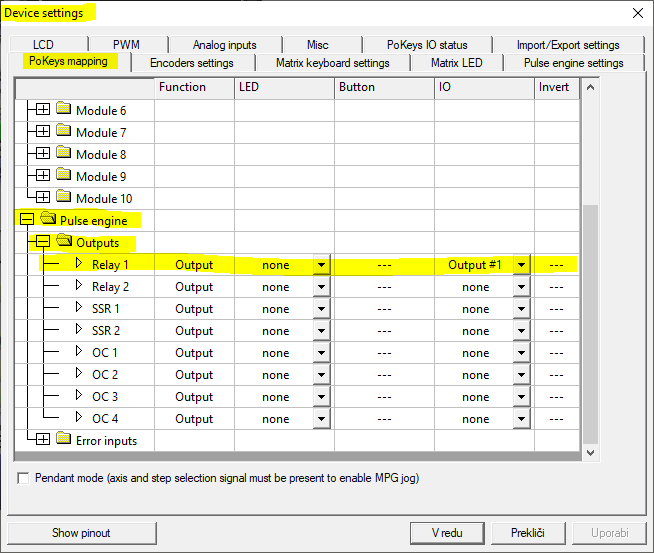

Cutter switch ON/OFF setup

For example, We will use the PoKeys57CNC onboard Relay 1 as a plasma turn ON switch. Go to Device setup -> PoKeys mapping -> Pulse engine -> Output and for Relay 1 select IO Output#1. Run G-code with M3 and M5 command and check if the Relay1 is switched On/Off.

Mapping Relay1 as a cutter switch ON/OFF

Mapping Relay1 as a cutter switch ON/OFF

Basics of Mach3 plasma G-code

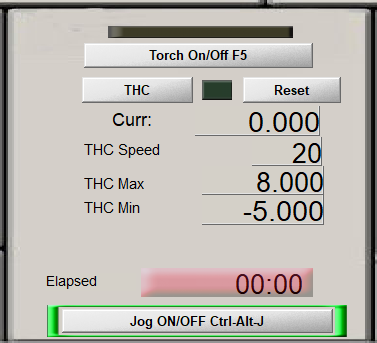

The THC mode must be manually turned on (the THC button is green). Use the M03 command in G-code to start (Torch-On) and M05 to stop (Torch Off) the plasma arc. Use code G31 for probing. Keep in mind that if THC mode is ON executing off the G-code will be stopped if the Arc_OK signal is not activated. THC Min and THC Max limit the range of motion of the Z-axis in THC mode. In case we would like a negative value for THC Min we must change the value in Plasma.xml file in Mach3 folder (search for THCMin and THCMax).

I suggest you install also one of the Mach3 Plasma screen set. How to do that we have already written in one of our previous blogs (Plasma THC screen set Mach3).

If you need information and a guide about stepper motor drivers, I suggest you read our blog on stepper motor driver.

Please also check our latest blog posts and products. It can help you to improve your machines or get some ideas on how to even make it a better

- plasma voltage divider

- Bipolar stepper motor driver – PoStep25-256

- PCB tester – PoStep25-256

- Homing sensor

- 4th axis for CNC

- Introduction to CNC hardware – electronics

- Plasma cutting equipment

- What is CNC plasma cutting equipment

- CNC plasma floating head

- Plasma cutter troubleshooting guide