Recently, one of our customers, Tomaž P., sent us a description of his project “DIY orchidarium”. He uses our USB I/O controller PoKeys57U as an automation control device. We are glad to hear our devices are not installed only in CNC control and flight simulator world but also used in such “green” projects as a greenhouse automation.

Below we publish an article from our user. He describes his orchidarium automation, using the PoKeys usb CNC controller as automation control device. Wonderful orchidarium! Thank you Tomaž!

DIY orchidarium automation using PoKeys57U as automation control device

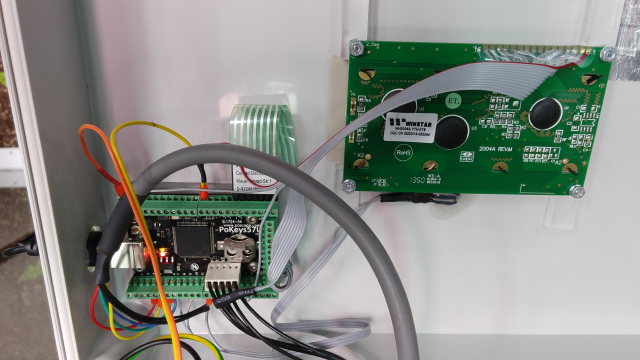

To minimize maintenance in orchidarium (Figure 1) all technical equipment should be controlled by suitable controller. On the market there are many of those controllers. Most of them they have basic or some specific functions without special custom need. If there is need to achieve lowest maintenance level with more advance functions, than you should choose an universal automation control device. I found out that the Pokeys usb cnc controller with its accessories (Figure 4,5) is the perfect choice for such automation.

Fig1. Orhidarium

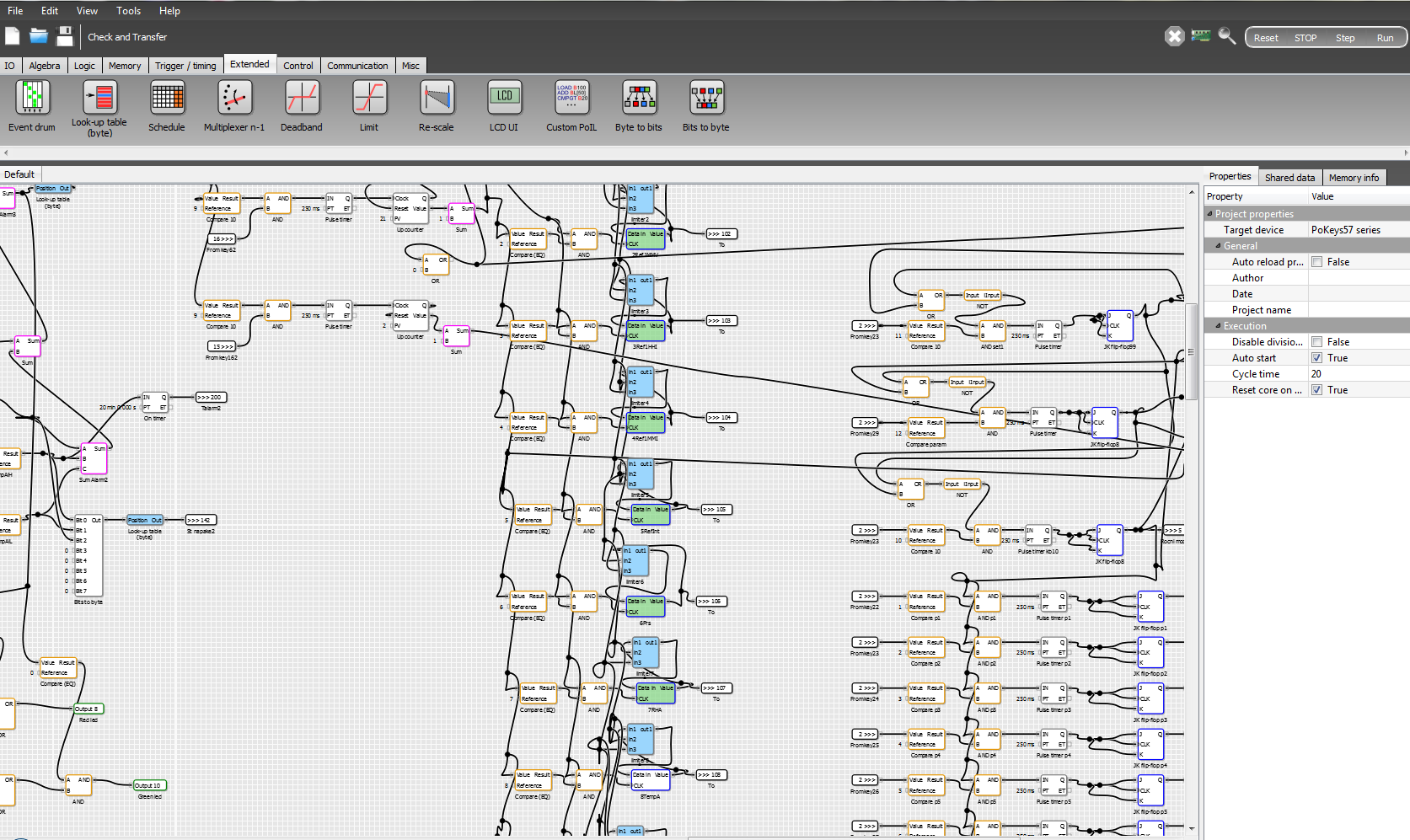

The Pokeys usb CNC controller offers most of the hardware and software functions. The controller has a wide area of I/O ports and communication protocols like i2c, one wire… Many different sensors can be easily connected on. The programming is made with logic symbols, connections with different blocks and even custom blocks. The controller has own real time clock which can be keep up in case of a power failure. Also some user parameters can be keep on the battery ram (15 byte). (Figure 2). Programming is intuitively and very complex solutions can be made.

Fig2. Small part of logic

Technical equipment

The PoKeys57U controls different technical equipment and parameters

– Lighting 2x80W T5 (3x)

– Ventilation

– High pressure pump

– 2 channel tap water spraying

– Ground watering

– Control ground water level

– Control level of water in tank (pump protection, water refill, tank full)

– Low and high temperature

– High temperature protection

– Target humidity

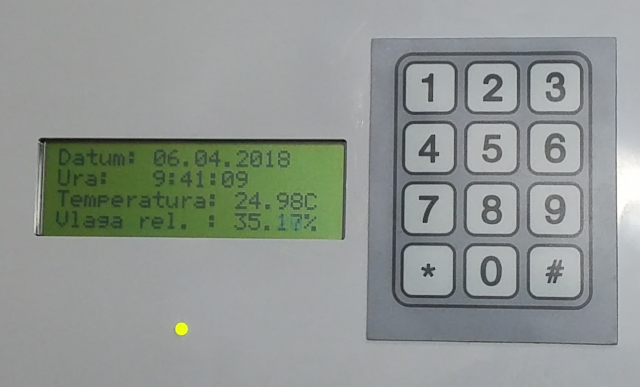

Statuses, parameters and manual mode are accessible directly from a menu which is displayed on lcd 4×20 (Figure 3). Therefore the user can change some of parameters (Lighting time On/Of, watering, different modes of operations, ventilation, humidity…) using membrane keyboard. If there is any event outside of the limits, user can see a message on lcd and check what is wrong (temperature, humidity, water level…). Additionally a two-color led diode shows, with different colours and blinking period, the current status.

Normally there is no need for maintenance. Everything is fully automatized. User only need to fill 25l tank with a tap water when is need it and than the PoKeys usb cnc controller takes care of the rest.

Fig3. Keyboard and lcd display

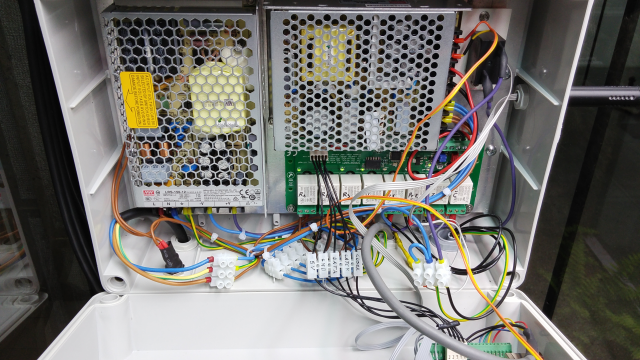

Fig4. PoKey57U usb cnc controller connected to lcd

Fig5. Smart relay PoRelay8 card and power supply

Fig5. High pressure pump and valves

Fig6. Level switchs – pump protection, water refill, tank full

Fig7. Level switch in ground for protecting roots of plants

PoLabs also offer other CNC electronics, check some our products and blog posts:

- Stepper motor driver,

- Stepper motor driver-complete explanation

- USB CNC CONTROLLER-PoKeys57CNC

- Homing sensor-PoHome1IRNPN

- plasma voltage divider

- Bipolar stepper motor driver – PoStep25-256

- PCB tester – PoStep25-256

- 4th axis for CNC

- Introduction to CNC hardware – electronics

- plasma cutting equipment

- what is CNC plasma cutting

- what is CNC plasma floating head

- Plasma cutter troubleshooting guide