In this blog post we are presenting you the plasma floating head for more precise cutting and how it can benefit your CNC plasma cutter with torch heigh control.

Table of Contents

What is CNC Plasma floating head

With plasma cutters, big sheets of metals are usually cut. These sheets usually don’t sit very flat on the plasma table and because of that, distance between the torch and the sheet can be different from one area to another. That leads to imprecise cuts and poor cut quality.

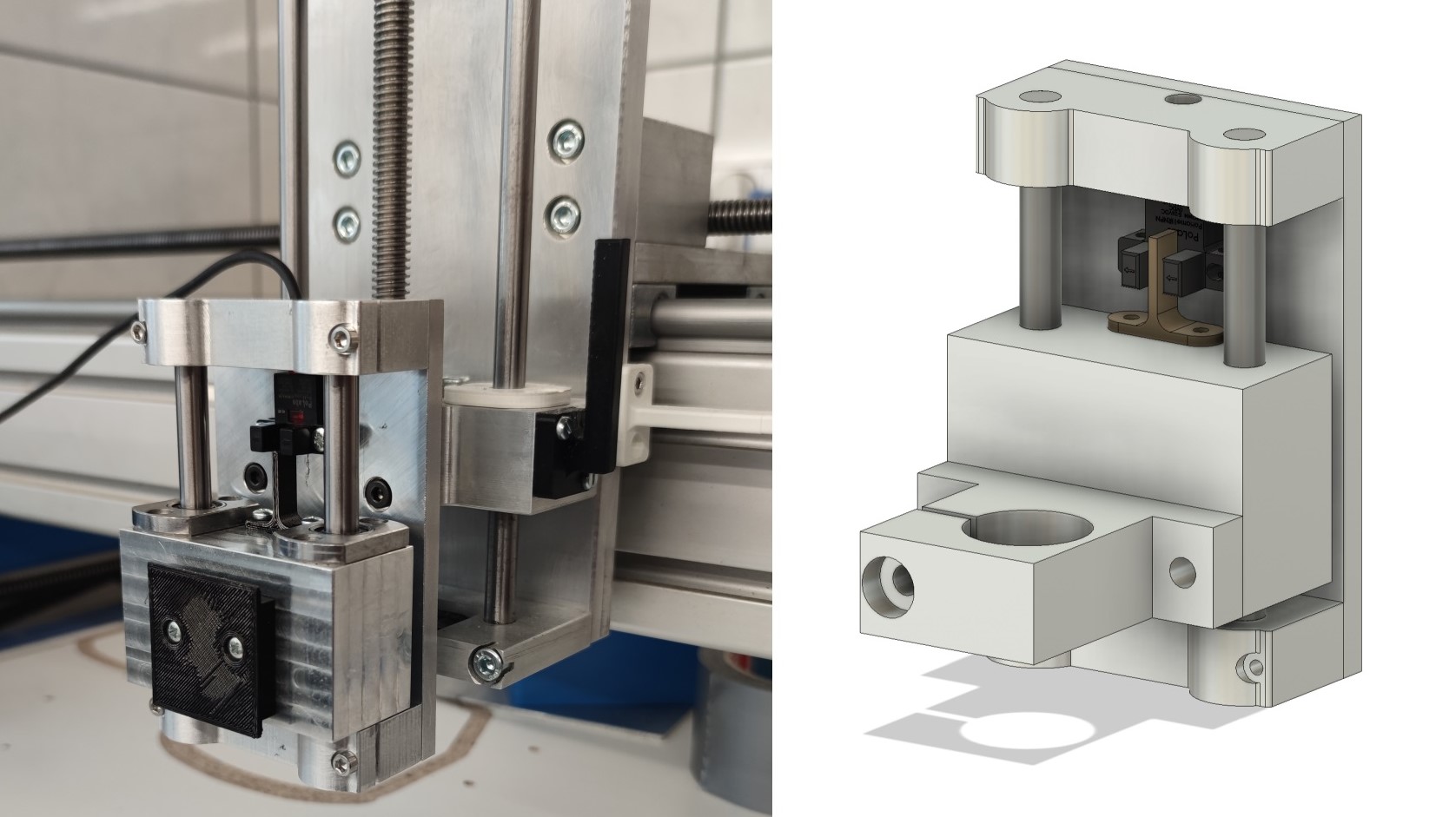

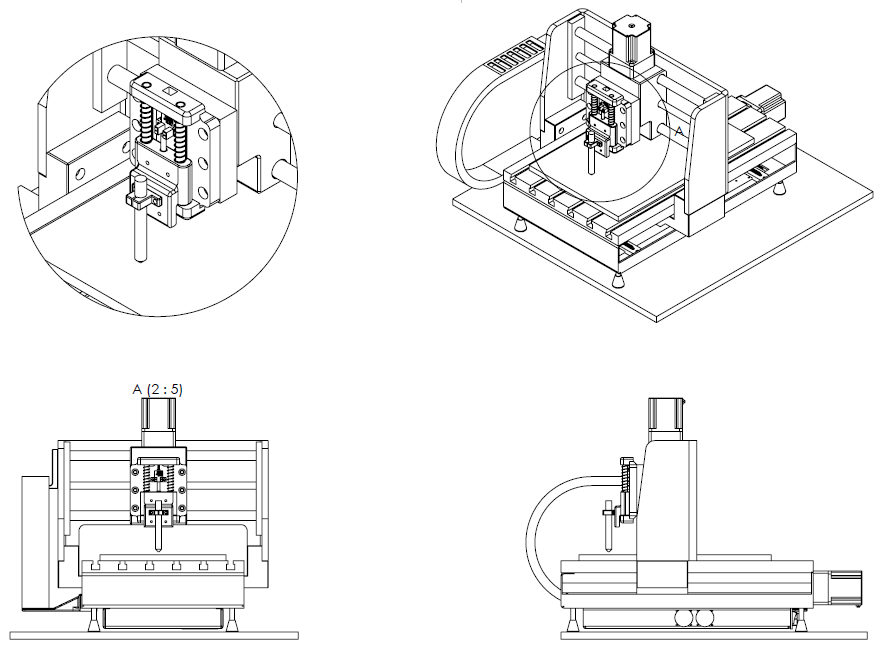

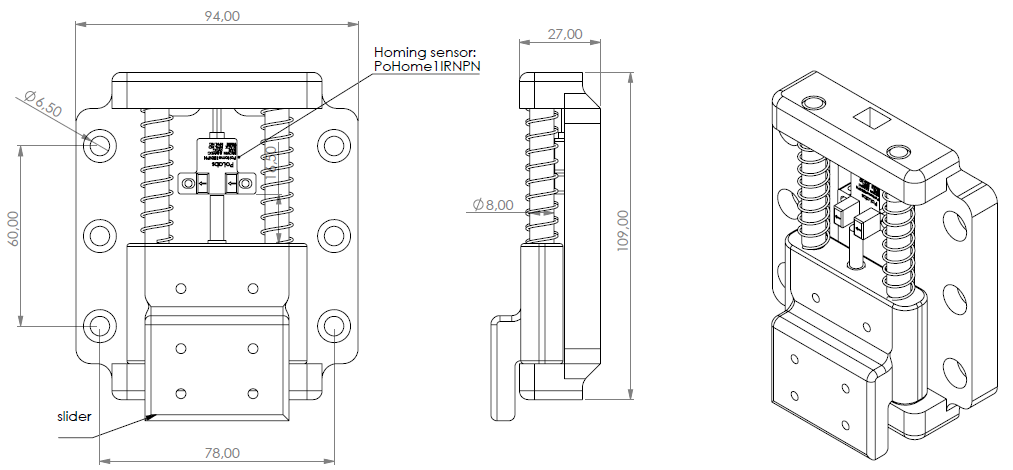

Plasma floating head solves that problem. The concept is very simple. It is another unit, mounted on top of the Z axis. It has a rail with carriage that is floating but is preloaded with springs downwards. There is a limit switch on the floating head, that is triggered when the carriage moves up for some distance.

The limit switch is used to measure the material’s top surface. When the Z-axis moves down towards the material, activated switch signals controller that surface of the material was detected and zero work position of Z-axis can be set.

The floating Z axis on a plasma machine is also safety feature that prevents any serious damage to your plasma torch in case it hits any obstacles located on the machine table.

What are main benefits of CNC Plasma Z-axis & Floating head

The main benefits of CNC plasma floating head are:

- Low cost modification on CNC machine,

- plasma floating heads are a very simple, robust systems.

- easy and low cost maintenance,

- easy setup and settings,

- safety feature,

- the probing accuracy of a calibrated floating-head is very good.

How to set up CNC Plasma floating head

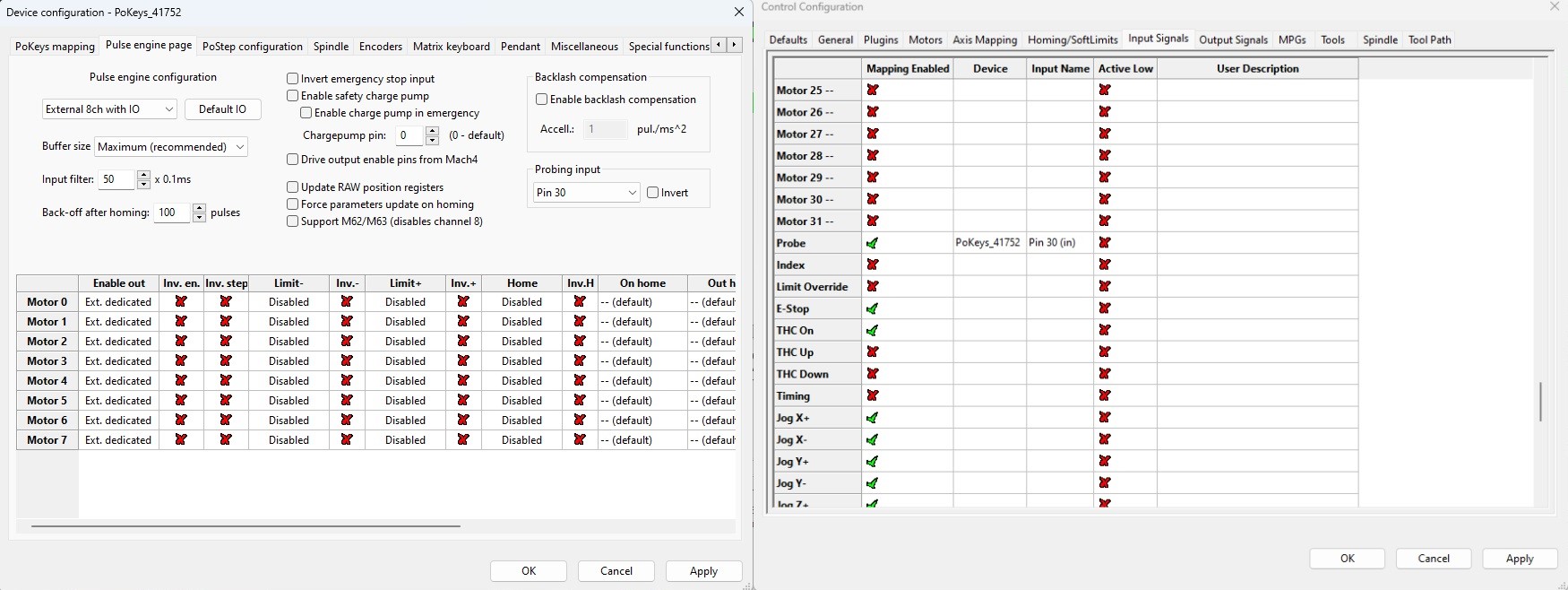

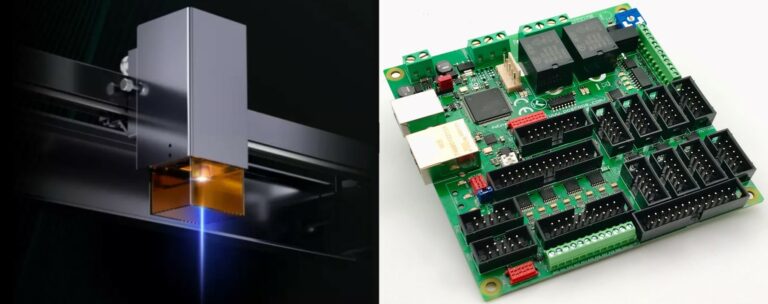

The floating head switch (Z-axis probe) has to be set up in Mach. We can select any native PoKeys pin as input for probing. In our case, we used AdapterPNPN because it offers galvanic isolation for the input pins. It is important for plasma electronics since there are a lot of electromagnetic noise. We selected Pin 30 as input and used NC wiring with our homing sensor.

Probing – G31

When the floating head is set up and switch is correctly wired and set up in plugin, we can test the floating head on the machine and cut the material.

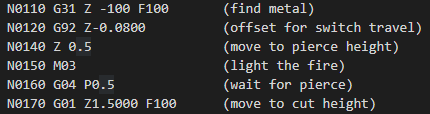

It is important to use the G31 code because with the G31 method you set up the floating head as a Probe. Then you must generate code like. Example of G31 code.

Useful information when working with CNC Plasma Z-axis & Floating head

Floating head & CNC plasma Z-axis is a low-cost modification that can help the machine work more safely. With our PlasmaSensOut unit it offers easy integration to the CNC control.

There is a lot of different kinds of floating heads on the market. It is important is to select/use the version which is the best fit on your CNC machine and is easy to set up and maintain.

For 3d models of floating heads and also other CNC electronics(PoKeys) you can find them on GrabCAD.

About

We develop and manufacture electronic products for many different areas and needs and also make some machines to make work easier, more productive and high quality. Here are some interesting projects- blog posts, please check.

- Plasma cutting equipment,

- Plasma cutter troubleshooting guide,

- What is CNC plasma cutting,

- Stepper motor driver-complete explanation,

- Bipolar stepper motor driver – PoStep25-256

- PCB tester – PoStep25-256

- 4th axis for CNC

- Introduction to CNC hardware – electronics