This is general introduction to plasma cutter setup and equipment with explanation of most commonly used nomenclature in that field. We will present the electronics that we offer for THC – torch height control for plasma cutters.

Table of Contents

What equipment is needed for CNC plasma cutter setup?

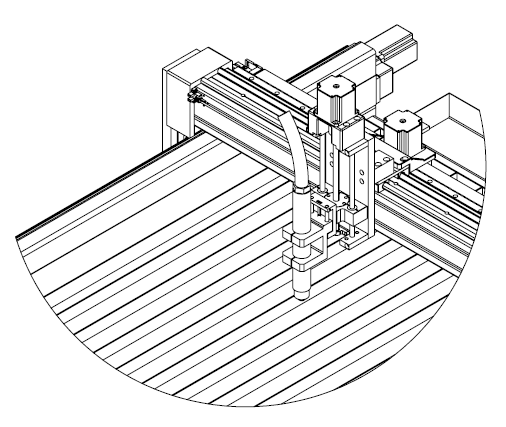

For plasma cutting setup, we need plasma source in form of plasma torch with appropriate power supply and electornics. Next we need CNC machine, usually in form of gantry style machine with X, Y and Z axis control. Plasma torch is mounted on the Z axis and in advanced setups that include THC function with floating head. Floating head with its function is described in our blog post.

Plasma machines should be properly designed and manufactured for such type of machining, considering slag, steel dust, moisture, high temperature. It is also important to consider the proper position of electronics devices on CNC machines, because of a lot of electromagnetic interference and disturbance.

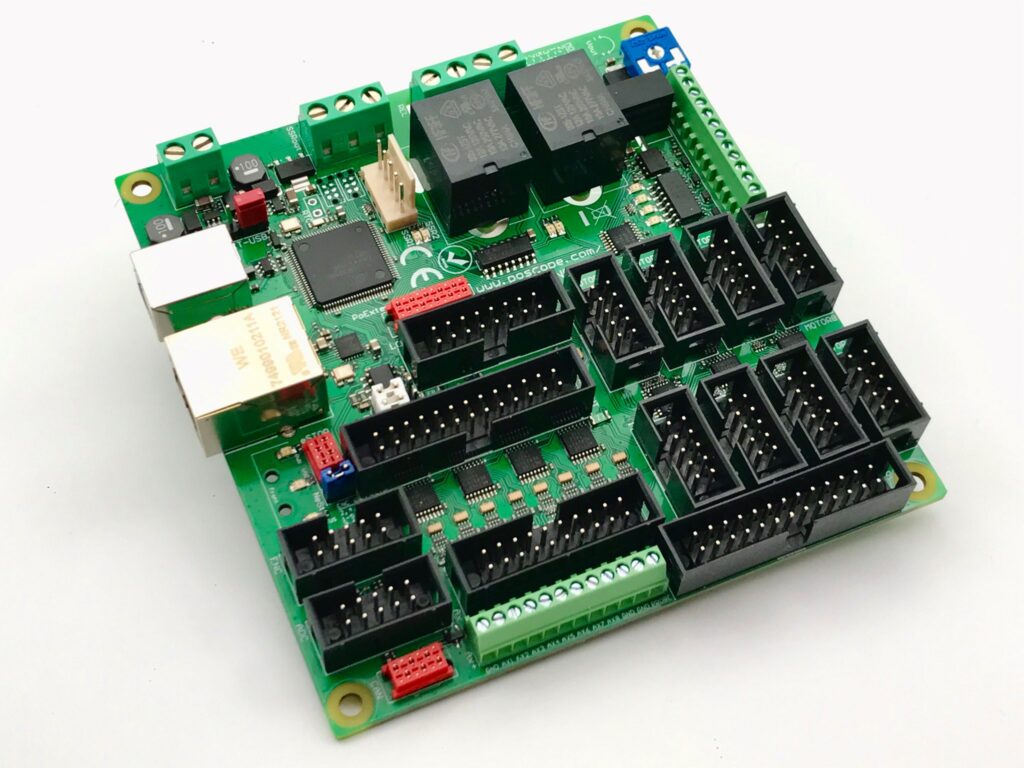

CNC controller

The Computer Numeric Control (CNC) is the brain of your system. It controls the moving of the machine as well as all the other input and output signals. With software such as Mach4 it makes unattended machining possible with executing the G-code that the operator provides.

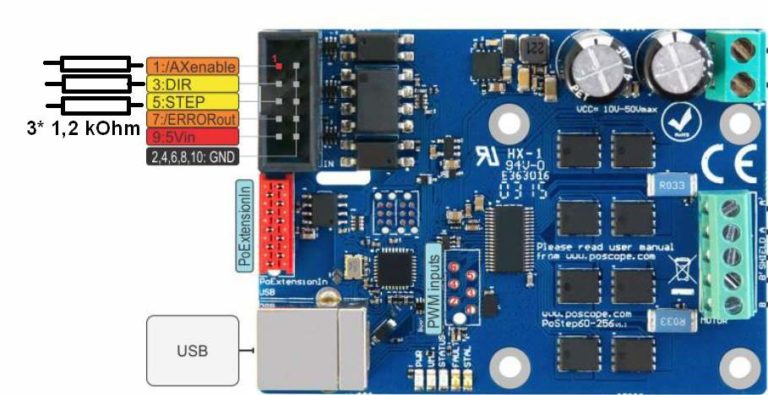

In case of plasma cutter setup, out PoKeys57CNC controller can move the appropriate axis as well as take care of THC control. Users can also program all other possible features such as on/off fume extraction, plasma on/off and other functionalities.

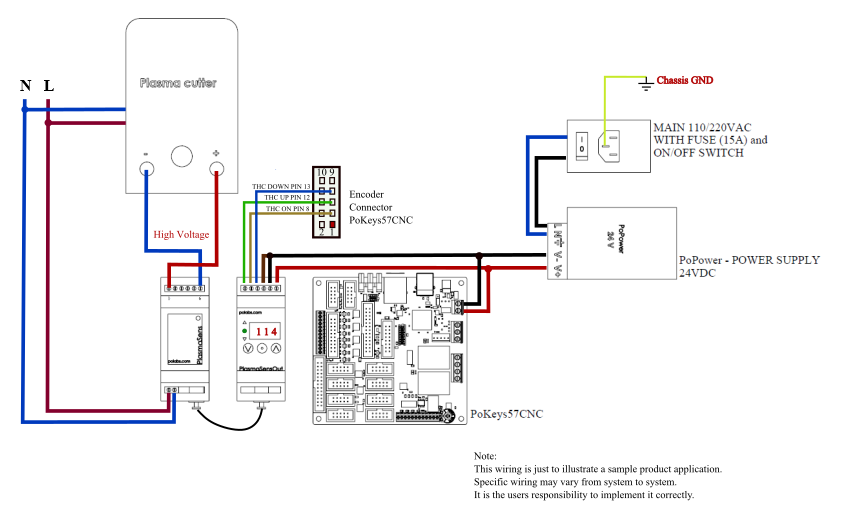

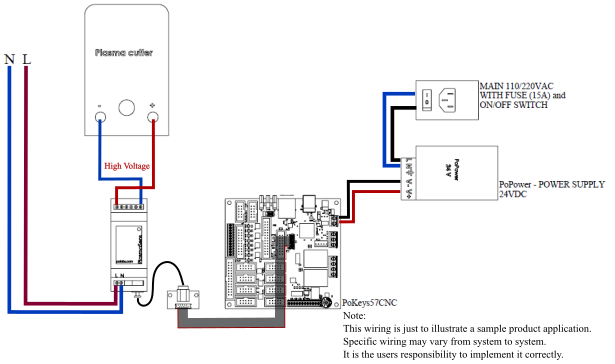

Cables and Wiring between plasma cutting equipment

With wiring of the plasma cutter setup special care should be taken. All the wiring around the machine with long cables can be source of errors in the controller and performance of the plasma cutter. The plasma itself uses very high voltage, especially when piercing the material. High voltage spikes can occur on long cables due to induction and electromagnetical noise.

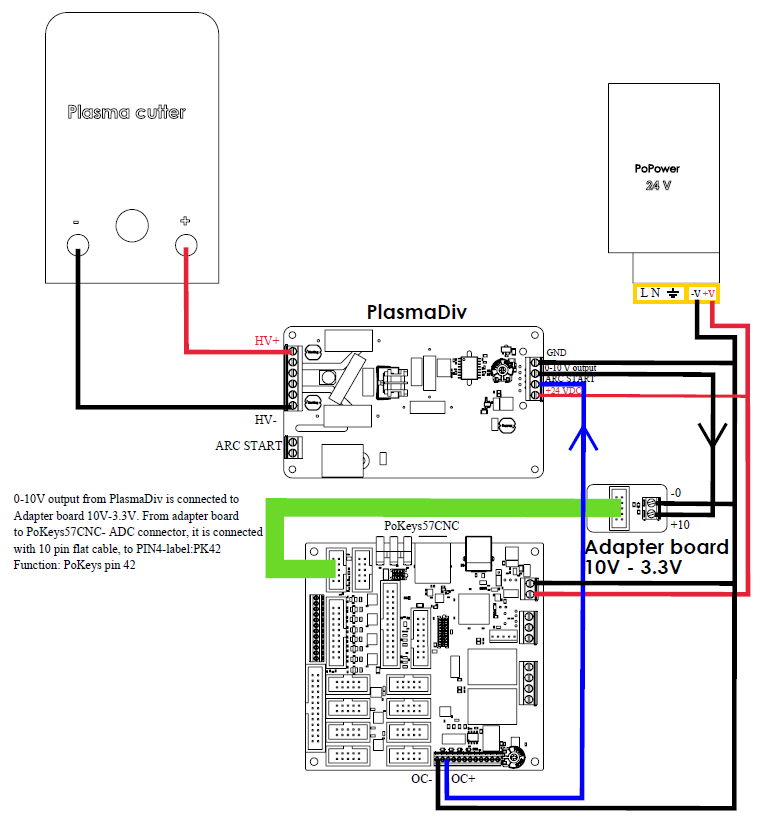

When wiring the cables around plasma cutter, it is essential to galvanically isolate all the signals that are connected to the electronics and PoKeys57CNC. We provide optical isolators such as Industrial digital input isolator and adapter PNPN. All the sensors, end switches and floating head switches should be wired through the optical isolation to protect the control board.

Our THC PlasmaSens and PlasmaDiv board offer optical cable that also galvanically separate the THC unit from the controller. All the control electronics should be kept and mounted in separate steel electrical cabinet that should be properly grounded. If possible, mains filters should be used in power supplies that are powering the electronics.

For PlasmaSens unit it is recommended to be mounted on the outside of the main cabinet with only optical cable going into the cabinet itself. All the connections should be as short as possible inside the cabinet as well. For signals outside the cabinet such as end switches and motor cables and others, it is recommended to use shielded cables with shields connected to earth on one side.

THC – Torch height control

If the CNC is the brain of your system, the Torch Height Control (THC) is your system’s eyes. Monitoring arc voltage ensures your torch or cutting head doesn’t get too close or far from the workpiece. THC works by sending a real time feed of the plasma ARC voltage to the motion control board – CNC controller, which then controls the Z axis with the torch to either lower or raise depending on how the voltage changes through the cut. The THC:

- Regulates the height of the torch throughout the plasma cutting process

- Helps your system to achieve the required cut quality

- Helps with consumables life (parts of the torch itself)

- Protects your torch or cutting head from collisions with the plate

Our THC controller options include:

PlasmaSensOut

PlasmaSensOut is a universal torch height controller (THC) for use with PlasmaSens torch height sensor device. The PlasmaSensOut is standalone controller that outputs the UP/DOWN and OK signals depending on the arc voltage. Controller does not get the analog voltage but rather digital signals for lowering or raising the Z axis with the torch.

PlasmaSens

PlasmaSens is a torch height sensor for use with CNC controller. It sends the real time data of the voltage via galvanically isolated optical cable to the PoKeys57CNC which can then perform the THC control with help of Mach3 or Mach4 and adjust and regulate the height of the Z axis.

Plasma cutter voltage divider

PlasmaDiv is similar device to the PlasmaSens but features advanced filters for direct plasma voltage. It also features isolated start signal with relay for the plasma ON/OFF firing which can be used to safely interface the plasma cutter.

Connection of the THC to your plasma cutter machine

The connection of our THC controllers to you plasma cutter has two options in case of all our controllers. The raw plasma voltage can be as high as 400V. It can not be directly connected to the sensitive CNC electronics, so the voltage divider is necessary. In most high end plasma cutters the voltage divider (usually 50:1) is integrated into plasma control box and there is output connector with already lowered voltage (usually up to 10V). In case the plasma controller does not have internal divider, our controllers have voltage dividers build into them. PlasmaDiv also has imrpoved filtering along with voltage divider.

Connection from plasma controller then leave us with two equal options:

- It is recommended to use already existing voltage divider if your plasma cutter has one integrated. That way you don’t have to deal with the high voltages and all the problems that come with it. LOW VOLTAGE from plasma cutter has to be connected to the LOW VOLTAGE terminals (0-10V) of our THC controllers.

- Connect the raw HIGH VOLTAGE directly from the plasma terminals to the THC controller on the HIGH VOLTAGE terminals. Be careful NOT to connect the high voltage to the low voltage terminals of the THC since it will destroy the controller immediately. Special care has to be taken with using the appropriate cables that are rated for such high voltages and it is recommended that the cables are not too long and shielded. Shield should be connected to earth to protect the environment from excessive electromagnetic noise.

How THC works

We covered the settings of plasma cutter setup in our other blog posts since they are slightly different for Mach3 and Mach4. But the function of the THC is the same. After the start fo the CNC program the THC gently touches the surface of the material (probing) to establish the Z zero distance from torch to material. Then it moves to predefined torch on height and fires the torch ON.

It will then again move the torch to the pierce height and start a pierce. The control will wait for a predefined time to pierce the material through and then move down to cut height. If the torch is too low, you risk a collision with the plate, too high you will get kerf too wide, as well as increase edge angularity, dross, and warpage. Once the X and Y-axis motion is started, the ARC voltage feedback control takes over to maintain the proper torch distance. It is important to maintain the cutting height of the torch trough the cutting process in order to archive good quality.

About

Polabs, develop and manufacture electronic products for many different areas and needs and also make some machines to make work easier, more productive and high quality. Here are some interesting projects- blog posts, please check.

- Adapter board 10V-3.3V plasma,

- Mach3 plasma setup,

- THC plasma cutter

- Introduction to CNC hardware – electronics

- CNC plasma floating head – Z-axis

- PCB tester – PoStep25-256

- Bipolar stepper motor driver PoStep25-256