There is very simple way to test your PlasmaSens THC controller with our PoKeys application. Just connect the PlasmaSens to PoKeys57CNC and follow these steps for torch height control test.

Connecting the PlasmaSens to the PoKeys57CNC

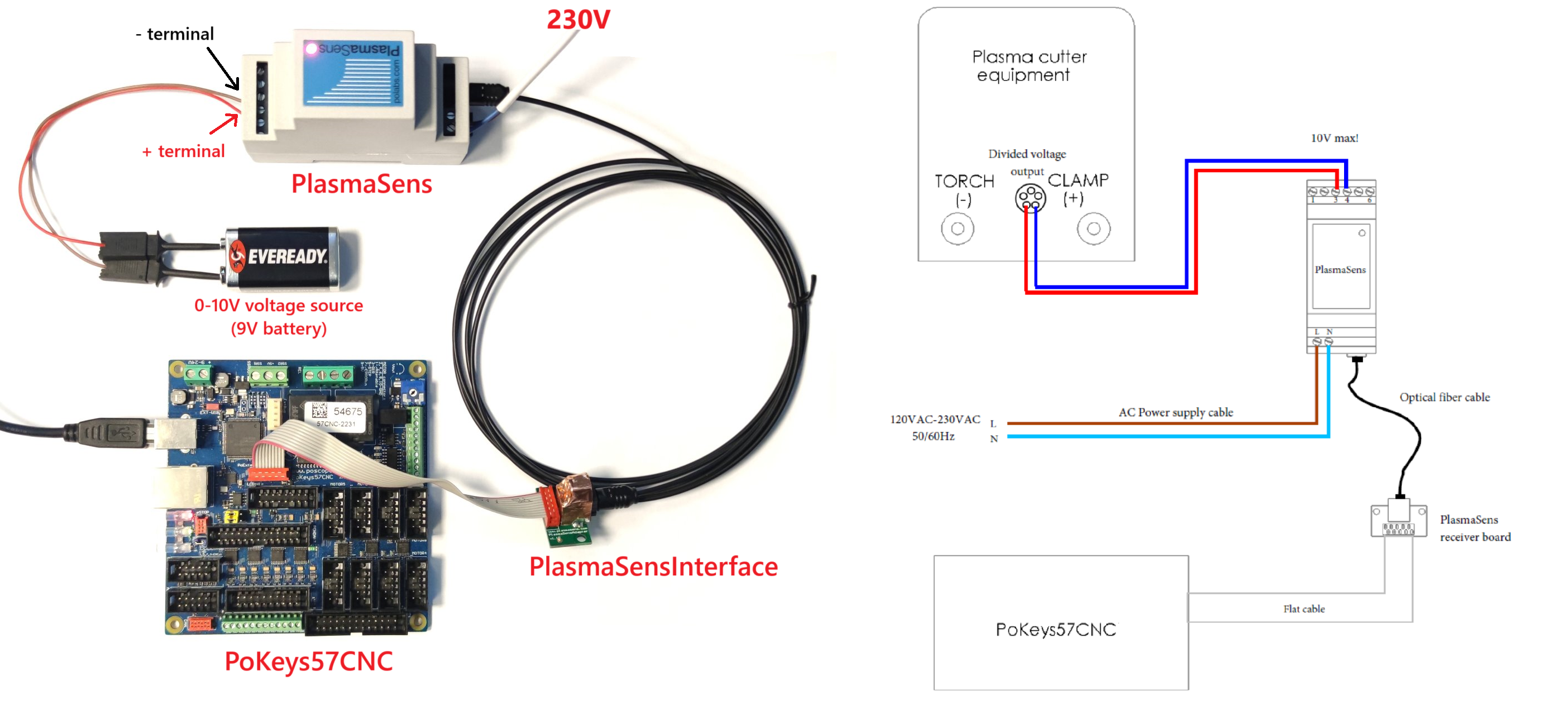

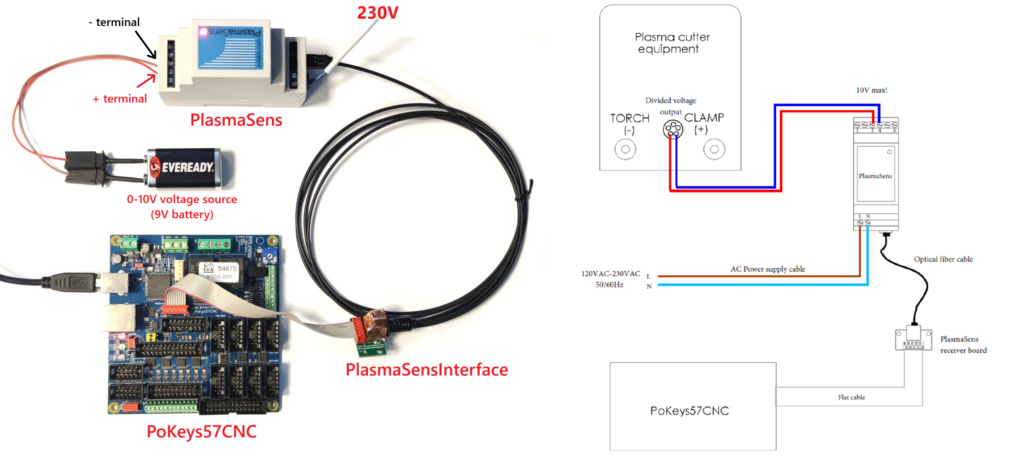

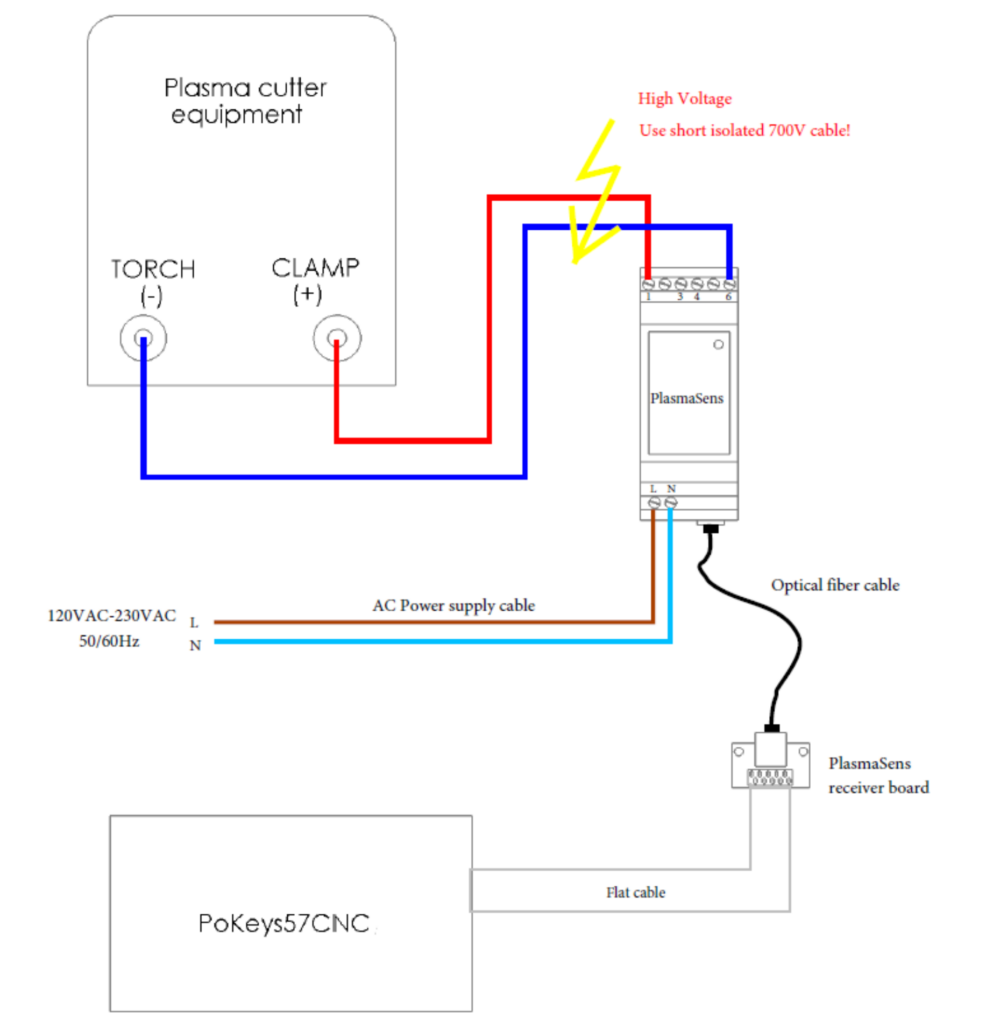

We offer different THC – torch height control options. PlasmaSens is most used with Mach and with our PoKeys57CNC motion controller. In this tutorial, we will test the functionality of the system. First, you need to connect the PlasmaSens to the PoKeys57CNC motion controller. They are connected via optical cable and PlasmaSensInterface board. It is essential to remove the cover from the optical cable before connecting it to the two devices.

PlasmaSens also has to be connected to the mains power (230V) in order to have the power supply for functioning but don’t plug it into the mains voltage yet. As a final step, there has to be voltage connected to the inner most terminals of the PlasmaSens voltage input. The inner terminals accept the voltage between 0-10V for which the regular battery is best fit for testing. Just be careful that you don’t mix up the + and – terminal of the battery.

If you want to connect the plasma cutter, you can also connect it via high voltage (outer most) terminals on the PlasmaSens.

Torch height control test – Testing the functionality

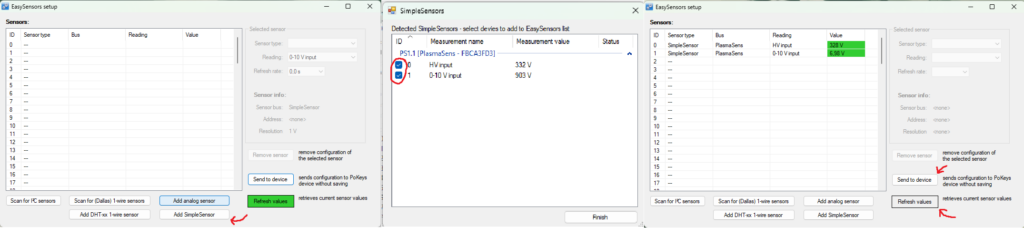

First step is to download the latest version of PoKeys software. Connect the PoKeys57CNC to computer via USB or Ethernet and open the application. Then update your PoKeys57CNC with the latest firmware as well. Then open the “EasySensor” tab under the “Peripherals“. Add SimpleSensor and mark both LV and HV inputs and click “Finish”. Then “Send to device” and “Refresh values” and the updated values should be present at each HV and LV input.

If you have plasma cutter connected you can make test cuts manually and observe the voltages on the EasySensor window. That should indicate that PlasmaSens unit is working as intended.

Conclusion

Please make sure that you are following the basic guideline for CNC wiring and plasma wiring for your machine. It will improve reliability and make sure that nothing gets damaged.

If you want to add THC – torch height control functionality to your CNC plasma cutter with Mach software please check the Mach3 plasma setup as well as Mach4 plasma cutter tutorial.