Every CNC machine needs a way of measuring the tool length. The techniques can range from manual measurements which can be suprisingly accurate to advanced measurements with laser tool setter that have guaranteed precision.

Why is tool length measuring necessary?

Tool length measurement in CNC is a fundamental process that ensures accuracy, efficiency, and safety of operations. Every cutting tool that is mounted in a CNC machine has its own length offset, which must be accurately measured and registered by the machine’s operator before machining begins.

Without precise tool length measurement, even the most advanced CNC machine can produce inaccurate parts, waste expensive materials and can risk serious damage to workpieces, tooling, or the machine itself.

Manual vs. automatic tool changing in CNC machines

There are usually two types of CNC spindles. There are spindles with collets where cutting bit is mounted in the collet. Collet receptacle is part of the spindle shaft with no secondary spindle interface. Between tool changes the tool length is always different because tool can not be inserted in the same position. Tool length has to be measured every time that tool is changed in the collet.

On the other hand, many high end spindles have taper interface. It can be any number of standard taper interfaces from ISO/BT to more advanced like HSK or CAPTO. The interface is designed to repeatably and accurately accept the tool holder with the tool. The main advantage of these systems is that you can have many tools prepared and change them very quickly between operations. They always have the same length and each have defined tool number with tool length offset in the CNC control. Tool length only has to be measured once when changing the tool in the tool holder.

Tool length measuring methods

Tool length in CNC machining can be measured using several methods. The most basic method is manual measurement using a dowel pin or gauge block. In this process, the tool is slowly jogged from lower position upwards while trying to slide a known reference surface under it. This process ensures that the tool can’t be damaged as it could happen in case of jogging the tool down. Typically a dowel pin is used. The machine operator then manually calculates and inputs the tool length offset. While inexpensive, this method is time-consuming, prone to human error, and not suitable for high-volume or precision work.

To improve accuracy and reduce operator involvement, many CNC machines use contact tool setters, which rely on a mechanical probe or switch. The tool physically touches a calibrated surface and the system records the Z-axis position at the point of contact. This method is more repeatable and less error-prone than manual techniques, but it still involves physical contact, which can cause tool fracture, especially with small or delicate tools. Over time, the probe itself may suffer from mechanical wear, requiring recalibration or even replacement of the tip.

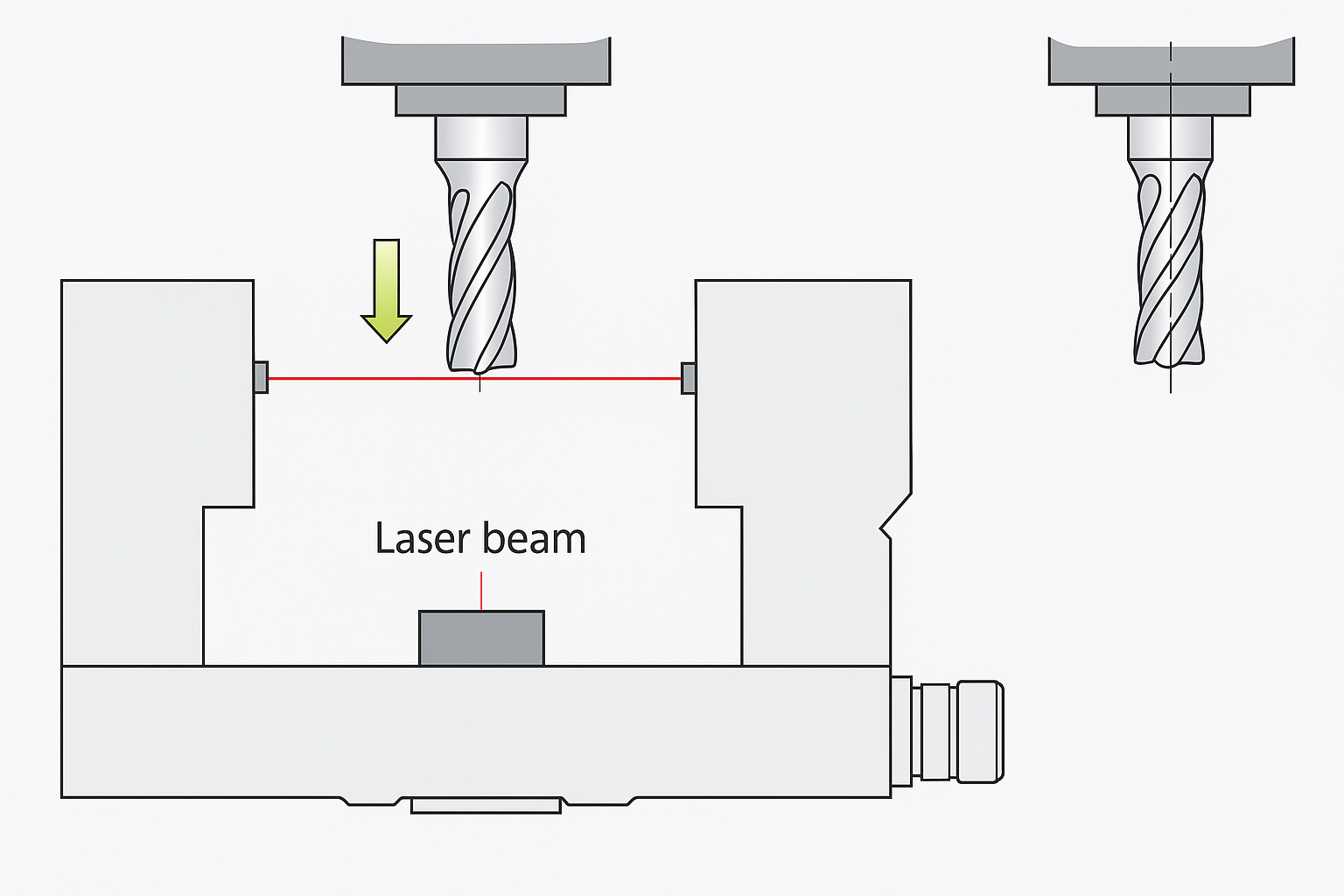

The most advanced and efficient method is the laser tool setter, which uses a laser beam to detect the exact point where the tool interrupts the light path. This method is contactless, eliminating tool fracture and mechanical wear entirely. Laser systems offer micron-level accuracy and long tool life as well as low maintenance and long service life. They’re particularly well-suited for modern CNC environments that demand high precision, automation, and minimal downtime.

How does laser tool setter work?

A laser emitter and receiver are mounted inside the CNC machine, typically in a protected zone near the spindle travel area. When a tool is moved through the laser beam, the system detects the interruption of the laser. Since it does not require physical contact, the process is extremely fast and causes no wear or deformation to either the tool or the measurement system. The tool length is then calculated and can be used as measurement or just for checking if the tool is broken. The process is very fast, reliable and efficient.

For integration to your CNC machine you can use PoKeys57CNC Mach4 controller and set up the laser CNC tool setter in plugin.

Conclusion

Accurate tool length measurement is one of the basis of successful CNC machining. Whether a workshop uses simple collet spindles or advanced automatic tool changers, knowing the exact length of the tool ensures parts are produced to specification, waste is minimized, and both tools and machines are protected.

While manual methods can work for low-volume or less critical applications, contact and especially laser tool setters dramatically improve repeatability, speed, and safety. By adopting laser-based measurement, CNC operators can achieve micron-level precision, extend tool life, and reduce downtime—unlocking the full potential of modern, high-performance machining.