Have you ever considered switching your CNC from LPT to USB? Let us point out 5 reasons to do so and use a USB CNC controller instead of an ancient LPT port.

1. LPT ports are disappearing

Computer industry these days has no more interest in maintaining LPT port functionality. This is a legacy port that enabled communication mostly with printers over the parallel bus. Printers have now moved on to USB. Moreover, the trend nowadays is in using high-speed serial communication (USB, HDMI etc.) that improves the user experience – focusing on lighter and more manageable cables, smaller and more practical connectors.

2. Increased maintenance costs of an old machine with LPT

If you own a PC with an LPT port, the maintenance of such a machine is becoming more expensive year after year. The replacement parts are usually not available anymore for purchase and scavenging other older machines brings reliability risks. If the parts are still available, they are mightly overpriced.

Stripped down version of Windows XP has been a popular choice for CNC machines. In 2014, Microsoft ended the support for Windows XP.

3. Use small, compact and fast PC to run your CNC

A mini PC with a pair of USB ports and monitor connector is all you need to run a CNC. You can even run the CNC machine from your laptop, what seemed to be impossible just a few years back.

4. No more glitches

Glitches happen when the PC momentarily does something else than producing continuous pulse trains. If these glitches are short, there might be no direct result. However, if glitches become larger, stepper motors may loose the position and even stop, ruining the machined object.

With external motion controllers, dedicated hardware deals with the pulse generation and glitches on the PC do not affect the generated motion.

5. Get additional I/O

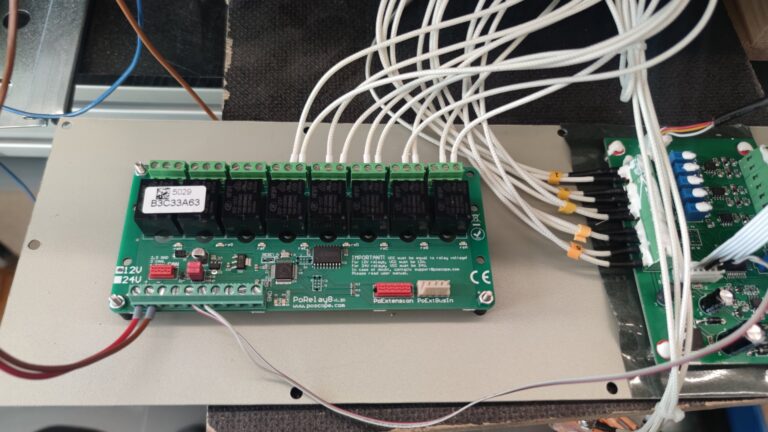

USB bus allows the external motion controller to host a large variety of additional I/O peripherals – now the same device can run CNC machine motors, display information on an alphanumeric LCD, handle manual pulse generators, read additional switches, switch external loads, potentiometers etc.

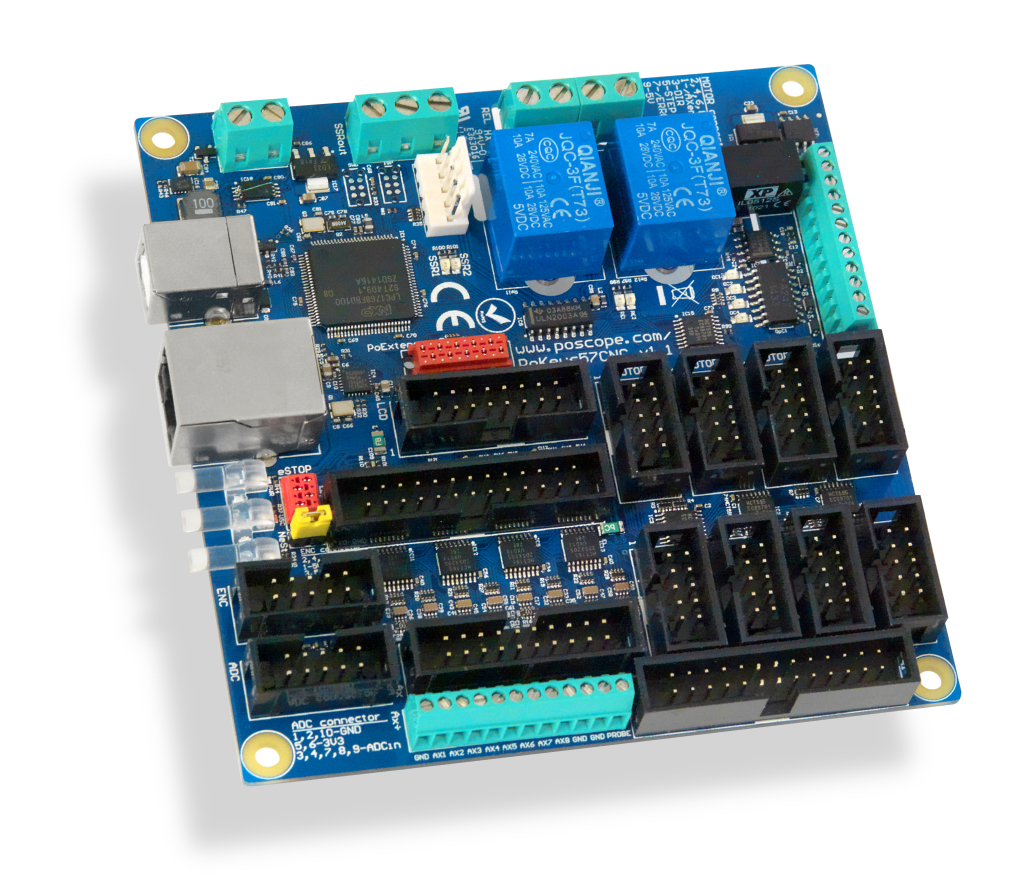

With PoKeys57CNC you even get a powerful programmable logic controller built-in, that allows peripheral tasks to be automated.

Switching your CNC from LPT to USB is easy

Usually this process is simple and straight forward. Instead of connecting your stepper motor drivers to the LPT port signals, rewire them to the external motion controller board (such as PoKeys57CNC). Get more information on PoKeys57CNC – affordable USB / Ethernet CNC motion controller

PoKeys devices support Mach3 and Mach4 software via freely available plugins (can be downloaded from PoLabs homepage).

Please check also some of our products:

- Stepper motor driver

- Stepper motor driver-complete explanation

- Homing sensor-PoHome 1IRNPN

- Bipolar stepper motor driver – PoStep25-256

- PCB tester – PoStep25-256