The new PoKeys device is finally released – dedicated CNC controller with integrated stepper motor drivers and easy to use software and plugin. It is is a blend between general purpose PoKeys device, CNC controller and stepper motor driver. It is intended for use with Mach4 CNC control software.

Device overview

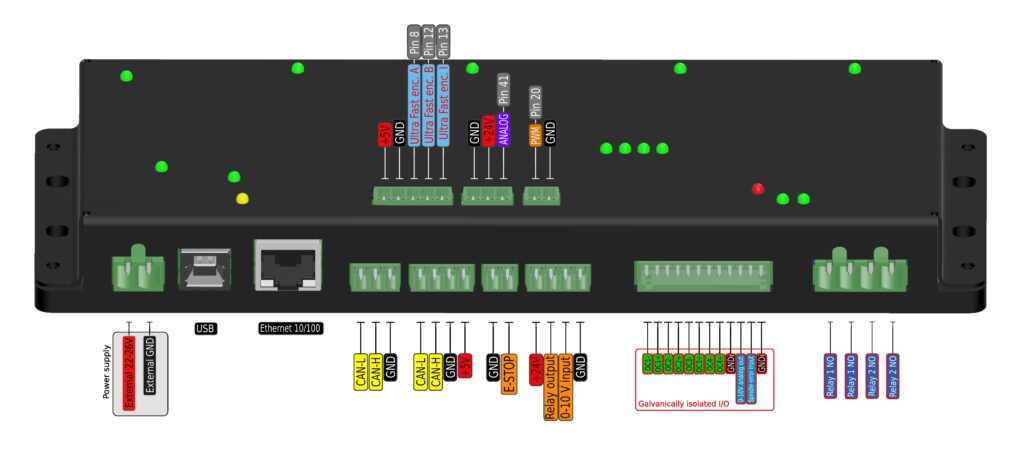

PoKeys57CNCpro4x25 is PoKeys device intended for stepper motor control. It is derivative of PoKeys57CNC controller with main added feature of 4x integrated stepper motor drivers. Device also contains dedicated connectors for connections with limit switches, CAN peripheral devices, spindle and VFD signals, plasma connection etc. In addition, 10 V analog inputs with 12-bit resolution are available. It connects with Ethernet and USB to the computer.

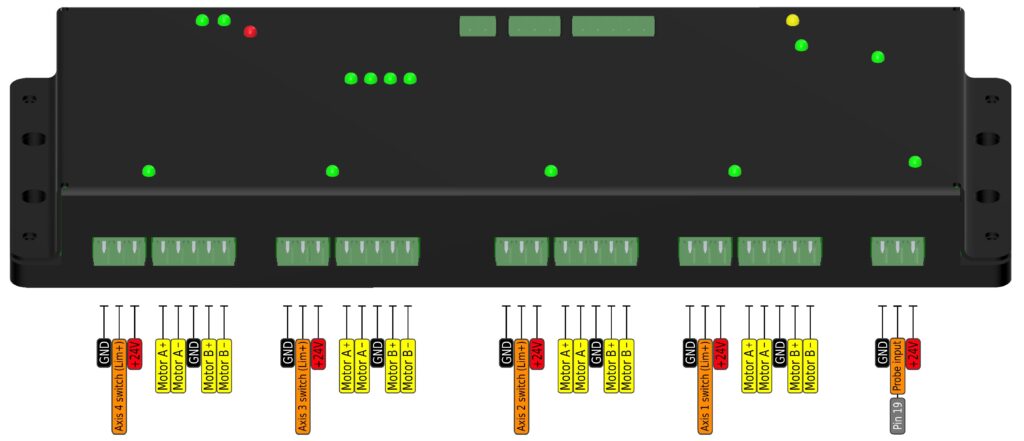

Integrated stepper motor drivers are 2.5A capable with up to 256 microstepping. They significantly simplify wiring between the controller and the stepper motor drivers. Having the drivers directly on board also enables the digital control over some of the driver functionality. We added current and mictrostep settings in our software so you can configure the drivers over the plugin or PoKeys software.

We spent a lot of time studying use cases for our CNC controller. The intention with this product was to make everything as plug-and-play as possible. The idea was to simplify wiring of all the sensor connections and other CNC periphery and make it as roboust as possible.

Periphery of CNC controller with drivers

- Stepper motor connection 4x

- NPN limit switch connection with 24 V power supply 4x

- CAN periphery – 2x connector with 5 V power supply

- Encoder interface with A,B and I inputs

- Analog input with 0-10V range and 24 V power supply

- PWM output with 5 V range

- Relay ouptut 2x with NO configuration

- Open collector output 4x

- Isolated spindle 0-10 V ouput and error input

- Probe input with 24 V power supply

- E-stop input

- Connector for plasma THC control

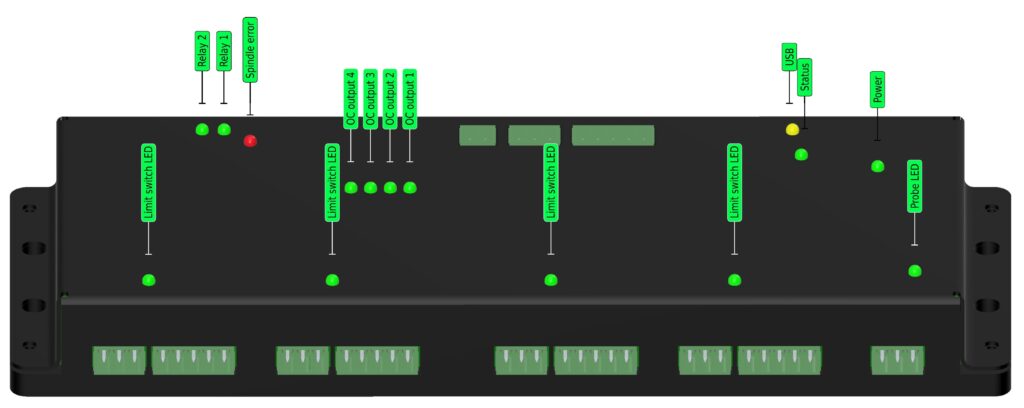

LED visual signalisation

Knowing how important visual clues are with setting up your machine and its operation we added LED on the outside of the housing for signalisation. That way it is immediatey clear when limit switch is triggered or other errors are present. It also shows when different digital outputs are triggered.

Why choose CNC controller with drivers

Compared to our other CNC controllers this one is very different. It is a more polished product with metal enclosure as well as easier to connect periphery. The main difference is that the customer does not need to buy separately the CNC controller, stepper motor drivers, digital input isolator etc. Everything is already inside one device, wired together and ready to use. You just need a power supply and you can connect your switches, motors etc. and have your machine running within minutes.

Integrated drivers might seem as a risk since in old hardware they could malfunction and it is very hard to replace them. For that reason we added extra protection to the drivers and whole circuitry to protect it from high voltages and spikes that might occur. The board also has internal temperature monitoring and it is set up that in an event of overtemperature it safely shuts down to protect itself.

We used it for more than a year on our machines and it performs better than expected. The new generation of stepper motor drivers enable smooth and reliable motion. The machine is much more quiet and can run for several hours without interruptions. We thoroughly tested the device on our own machines and polished the product to the state where we can safely say that we offer state of the art device for your machine.